Selecting suitable printed boxes

Choosing an appropriate print type for your industry and application

Whilst the ability of your corrugated packaging to protect your goods in transit is essential, using printed cardboard packaging can also have significant benefits for your brand and business.

But which type of print should you use?

In this guide, we’ll set out the four main types of printing that can be used for transit, retail, or eCommerce packaging, the advantages and disadvantages of each method, the suitability for different markets and uses, and how to decide on which method is right for your business and application.

Contents

Introduction

Why does how you print your boxes matter?

Your brand and its perception are essential to your business’s success.

It helps you win new business, enables you to maintain relationships with your customers, makes your products recognisable in a sea of rival and alternative products, and gives you a point of difference.

Ultimately, it can be the difference between driving sales and losing market share. Getting your packaging artwork wrong can be disastrous.

Your packaging has a crucial role to play in this; in fact, printed cardboard packaging is not only a way to protect your products whilst they travel through the shipping and transportation process. Increasingly, it is a way to present your products, advertise your business, and increase brand awareness.

To achieve this and make your packaging look as eye-catching as possible, there are a number of print options available. Each printing technique has a range of benefits (and limitations) specific to it, however.

Choosing the right one can make a significant difference to the success of your packaging.

Printed cardboard packaging options

The standard options when manufacturing printed cardboard packaging

So what are the primary print types you can choose from when sourcing corrugated packaging? Well, in no particular order, here are the options you should be considering:

- Silk screen print

- Flexographic (flexo) print

- Litho laminated print (lithographic)

- Digital printing

In this guide, we’ll provide further details on each method, along with its advantages and disadvantages. Whether you require high or low print runs, there will be an option that perfectly suits your packaging project.

Silk screen printing

Simple print method for bold designs and low volumes

Silk screen printing is one of the oldest and most basic forms of printing, yet it can still be used for printed cardboard packaging.

It is a print technique that uses a mesh to transfer ink onto a material. Despite its simplicity, this technique can produce excellent-quality single- or two-colour images.

Silk screen printing uses a stencil (or multiple stencils if using more than one colour in the artwork).

This sees a design imposed onto a screen of polyester or a fine mesh. Blank areas are coated with an impermeable substance so that ink can’t transfer through, whereas the image area is made of a porous material, which allows full ink coverage on the substrate.

During printing, the ink is forced through the screen, which is mounted on a frame using a fill blade (or squeegee).

When used as a packaging material, the board is generally screen-printed before being converted into a box or display. A clear benefit of this method is that it can produce higher-resolution images than many other techniques.

Due to the setup time and the process’s manual nature, this form of printing is rarely used for corrugated packaging (unless very low runs are required). It is also only really suitable for transit packaging that carries basic branding, due to the limitations on colours.

That said, this method is ideal for printing Correx® packaging or protective cases, which are generally produced in lower volumes.

| Advantages | Disadvantages |

|---|---|

| Cost-effective for low quantity print runs. | Long preparation times before printing can begin. |

| Produces a high-quality image on corrugated cardboard. | Minimum order numbers are require due to the lengthy setup process. |

| Can print onto a multitude of surfaces, including cardboard, plastic, and Correx®. | Due to the manual nature of the process, it is not suitable for mid- to high-volume use. |

| Creates long-lasting images that will not easily rub off with use. | There can be restrictions on the size of the graphic that can be printed. |

| Costs can increase if the design contains a large variety of colours. |

Flexo-printed packaging

Perfect for simple, striking print in mid to high volumes

Flexography (flexo) is a printing process that uses a flexible relief plate; it is often referred to as a modern-day version of letterpress.

One of the main benefits of flexographic printing is that it can be used to print on a wide range of substrates (materials), including plastic, foil, brown paper, cardboard, and other packaging materials.

Flexographic printing begins with the development of a flexographic plate. The technique uses plates with raised images. Only the raised images come into contact with the substrate during printing and deposit ink onto the material, thus generating the printed image.

Flexographic plates are made of a flexible material such as plastic, rubber, or UV-sensitive polymer (photopolymer). This allows the plates to be attached to a roller or cylinder for ink application.

Flexographic inks, unlike those used in lithography, generally have a low viscosity. This enables faster drying and, as a result, faster production, leading to lower costs.

This also makes flexo well-suited for the food industry. In fact, press speeds of up to 600 metres per minute are now achievable with modern printers.

Whilst flexographic printing can be used for full-colour printed cardboard packaging, this method is better suited to 1-3-colour, bold graphics in high volumes.

| Advantages | Disadvantages |

|---|---|

| It can be used to print on a wide range of absorbent and non-absorbent materials. | Images tend to be simpler because they can't produce intricate work. |

| Images can be printed in a wide range of colours, enabling vibrant image production. | Newer techniques can generate results more quickly and with a crisper finish. |

| Uses fast-drying inks, which might be solvent-based, water-based, or UV-curable. | The cost of printing plates makes it unsuitable for low-volume runs. |

| Cost-effective and economical for large volume runs. | Flexography can produce poor shadows. |

| Ink evaporates quickly, making it safe for use on flexible food packaging. | Potential for issues such as bleeding and pin-holling to occur on the finished product. |

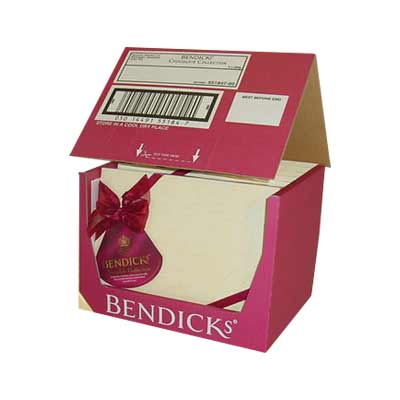

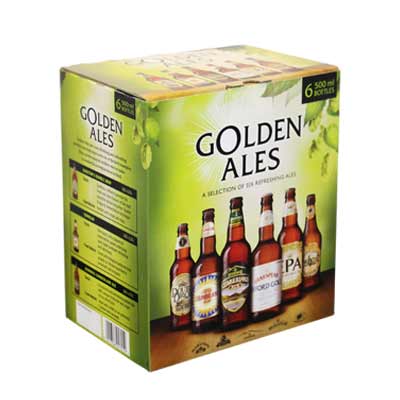

Litho-printed packaging

Exceptional print quality for high-volume requirements

Lithography is the most commonly used high-volume commercial printing technique.

The image to be printed is transferred from a computer to a printing plate and cut into it using a laser.

This ensures accurate reproduction of the image onto the plate and provides a high-quality result. It also allows for full colour, photographic-quality images.

The process is based on the repulsion of oil and water. The image to be printed is coated with ink from rollers in the printing press. The areas that are not to be printed attract a coating of water and, as such, repel any ink and remain unprinted.

Lithographic printing can be achieved on a traditional printing press or on a sheet feeder. The benefit of using a sheet feeder is that material can be fed into the press one sheet at a time at a very high speed, achieving quick results.

However, this makes it unsuitable for printed cardboard packaging. Whilst cardboard is a strong and versatile material, it can be difficult to print directly onto it due to its thickness and also the ridged surface (created by the fluting).

As such, when used for packaging, the design is printed on paper, which is then laminated to the face of the corrugated board (hence the common term “litho-laminated”).

This not only produces a better print quality, but also does not affect the fluting or structure, which may be altered if passed through a press.

| Advantages | Disadvantages |

|---|---|

| Achieves a high-quality and consistent image every time. | The nature of the technique makes the setup expensive. |

| Suitable for high-quality photographic imagery. | Due to the complex setup, lithographic printing can take longer than other techniques. |

| Cost-effective for high volumes as the unit cost decreases with increased quantities. | There is no option to amend designs once the late has been set up and printed has started. |

| Able to cope with long runs without losing quality. | Smaller colour gamut, therefore colours can be less bright. |

| Can easily produce specialist finishes such as Pantone spots and metallic colours. |

Digitally printed packaging

Exceptional print quality for high-volume requirements

Digital printing is a method of printing that uses a digital-based image and prints directly onto the chosen material.

Rather than using traditional printing press techniques, digital printing uses large-format laser or inkjet printers, which deposit pigment or toner onto a wide range of materials.

As such, there is no mechanical setup associated with digital printing as there is with more traditional techniques such as Flexography or Lithography.

Instead, the images are sent digitally to the printer from design software. This means images can be easily amended to ensure the best results, even once printing has begun.

Digital printing is an option for projects that need to be completed quickly. Whilst the cost-per-page of printing can often be higher than traditional techniques, this cost is offset for low volume runs by the fact that there are no mechanical setup costs or need to purchase or replace printing plates.

As well as the cost and speed at which images can be printed, digital printing can also improve image quality.

Due to the non-contact nature of digital printing, the risk of image distortion is significantly reduced, which can often happen with analogue techniques.

In addition, digital printers do not require the material to be tightly held or stretched during the printing process, meaning more material can be printed onto, giving designers more choices.

As with litho-printed cardboard packaging, photographic-quality images are easily achieved, although Pantone colours and metallic tend not to be supported.

It does allow for changing designs and dynamic elements, such as promotional codes and customer personalisation.

| Advantages | Disadvantages |

|---|---|

| No plates or complicated setup means a fast turnaround of orders. | It can be hard to match Pantone colours (branding may not be reproduced as easily). |

| Easy to generate proofs before printing runs begin, with amendments easily achieved. | Specialist finishes, such as metallic, are not as easily achievable or cost-effective. |

| Artwork can be amended during production with no need for new plates or setup. | Quality can be inconsistent, as some materials produce better results than others. |

| Enables bright, vibrant images on materials including paper and corrugated board. | Expensive on longer runs due to printing times. |

| Cheaper than traditional options for low-volume printing jobs. | There is less control over the colours that are produced by the printer. |

| Allows for personalisation and variable aspects. |

Which method is right for you?

Deciding on the best printed cardboard packaging for you

Despite having all this information, it can still be challenging to determine which one is best for your specific application.

As a general rule, silk screen printing is not suitable for corrugated packaging unless you are looking at very low volumes (e.g., under 100) and only require basic one- or two-colour graphics.

It is, however, an ideal choice for printing Correx®, plastic packaging, or even protective cases.

Flexographic printing is ideal for printed cardboard packaging that requires bold and striking graphics.

This makes it a good choice for transit packaging, but less so for retail applications. It is reasonably cost-effective regardless of print run, but the cost of the plates needs to be justified (ruling out very low volumes).

Litho-laminated printing is the best choice if you need the highest quality print. Photos and intricate graphics can be reproduced easily, making them perfect for retail packaging and point-of-sale (POS). However, the cost of the plates and setup means lead times are longer than with other methods, which is not cost-effective for low-volume runs.

Finally, digitally printed packaging offers an alternative to lithographic (and flexo) methods.

It can be cost-effective at very low volumes (due to no printing plates used and minimal setup costs), but its print speed makes it unsuitable for high volumes. It can produce results comparable to lithographic, including photographic imagery, and can be used for personalising packs to (as elements can change between individual prints).

Summary

Your perfect printed cardboard packaging

All four of these printing options can be sourced directly from GWP Packaging and applied to your packaging.

Our team of experienced staff will be able to offer impartial advice on the printed packaging option that is right for you and your business, based on a range of factors (budget, structural design, end user, etc.). It will ensure that your products gain the attention they deserve.

Share this article

Further reading

About the author

David joined GWP Packaging in 1995. His extensive knowledge and experience of corrugated packaging means he is widely regarded as an expert on this topic.

Products in this guide

Get in touch

Related guides

10 packaging artwork mistakes (and how to avoid them)

Litho vs. digital print for packaging

11 tips and ideas for successful branded packaging

18 bitesize tips for packing postal orders and eCommerce fulfilment

21 tips to prepare your warehouse for peak season

11 ideas for successful packaging during peak season demand

Temporary picking bins – 12 ways they help with seasonal demand

7 facts on the importance of eCommerce packaging

Analysis: Stock vs. custom eCommerce packaging

eCommerce shipping – the crucial role played by packaging

eCommerce unboxing experience and best practice

Peak packaging Monday – what is it, and does it affect your business?

Advanced tactics to improve order picking and packing

Corrugated board grades explained: types of cardboard

Transit packaging symbols (Meaning and Downloads)

Branded and printed sample cases – 9 visually striking ideas