Aviation packaging solutions for the aerospace industry

If your business is part of the aerospace industry in the UK, you’ll be acutely aware that your aerospace packaging has little margin for error.

Aerospace packaging typically protects extremely valuable, specialist, and fragile parts. Packaging solutions for the aerospace industry can be single-trip packs or returnable solutions reused throughout the supply chain. It must also meet various aerospace packaging standards, such as ASA (Aviation Supplies & Academics) or Mil-Spec packaging requirements.

At GWP, we have a proven track record in supplying fully bespoke, highly engineered aerospace packaging solutions. Our JOSCAR (Joint Supply Chain Accreditation Register) membership for aerospace and defence packaging, plus extensive experience, ensures your products get a precisely optimised level of protection.

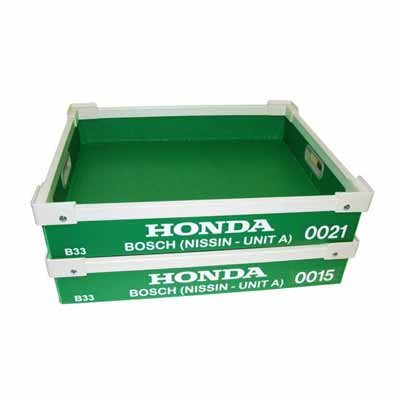

Returnable aerospace packaging

Reusable supply chain packaging tailored to aerospace requirements.

Large aerospace parts packaging

Heavy-duty packaging and cases for large parts and assemblies.

Single-trip aviation packaging

High-performance corrugated packaging options.

Specialist electronics packaging

Protection from static for electronics parts, including comms gear, navigation, displays and similar componentry.

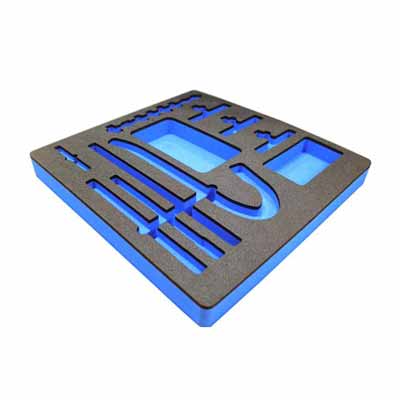

Aerospace tool cases

Tool storage and organisation for aerospace engineers and service technicians.

More info on aerospace packaging

The aerospace industry in the UK is second only to the United States of America in terms of size and turnover, with a global market share of 17% in 2019.

However, in addition to the global household names that dominate the UK aerospace industry, numerous supporting companies manufacture tools, parts, and components for this sector.

Aircraft packaging protection

Precision engineering. These two words effectively sum up the aerospace industry.

It explains the pressures put on companies operating in the industry, regardless of their size, turnover, or position within the supply chain. It can help understand the value of products and turnover of aerospace manufacturers. It describes how there is no space for error in this sector.

The slightest misalignment, a fraction too much pressure or even the slightest component damage (such as a hairline fracture invisible to the naked eye) can prove catastrophic.

As a result, the packaging used by aerospace companies often needs to be as precisely engineered as the parts and assemblies they are transporting.

Various parts, including ailerons and rudders, wing ribs, engine parts/cowls, propeller and helicopter blades, doors, fuselage sections, and the fixings used to assemble them, must arrive at production lines in perfect condition.

ESD safe aerospace packaging

Another factor to consider is the increasing use of specialist electronics within the aviation industry.

Whilst these are revolutionising what is possible and the performance of the products they enhance, there are drawbacks and challenges. One is the threat of electrostatic discharge (ESD), which is, in essence, atmospheric static.

Static can cause significant damage to electronics and microchips during manufacturing, assembly or storage. This damage often cannot be seen until it is too late.

As such, electronic components such as communication systems and onboard instruments require both physical and ESD protection.

Source aerospace packaging

With such a focus on precision engineering within this sector, at GWP we take a similar approach to your aerospace packaging.

Our approach understands that extremely valuable or specialist parts cannot suffer damage in transit. That the protection levels of your packaging may need to be calculated and tested before being acceptable to transport specific items.

That ultimately, the quality of engineering and manufacture is hugely important in aerospace packaging.

A selection of businesses that trust our aerospace packaging solutions

Aerospace packaging companies

At GWP, we have the product range, design capability, engineering focus, and experience (over 30 years) to be the perfect strategic partner for any company operating within the aerospace industry.

The engineering approach that is part of our culture ensures that your aerospace packaging offers the optimum level of performance for your specific application. And unlike other packaging manufacturers, this doesn’t mean over-specifying your packaging to prevent transit damage whilst vastly increasing the costs for no reason.

Through testing and using highly specialist software, our experienced design team can tell you precisely what your packaging needs to do to protect your products.

It does not matter whether this packaging needs to be manufactured from corrugated cardboard, Correx®, a variety of foams, or even moulded plastic. How GWP is set up ensures that we are one of the few companies that can supply all these materials and even combine them as required.

So, if you are not happy with your current packaging, have a new project coming up, or simply need some advice on the best aerospace packaging solution for your business, please get in touch.

Protective packaging

Packaging by market

Related guides

Free PDF download

Get your free guide to discover seven ways to reduce your costs using Correx®.

01793 754 444

Mon – Fri 08.00 – 17.00

info@gwp.co.uk

Email a packaging expert