Achieving customer satisfaction

Your bottle boxes should offer more than just transit protection

The key consideration when sourcing bottle boxes is, quite rightly, whether they can protect their often valuable and frequently fragile contents during postal or courier transit.

However, this focus on protection can mean that several other important factors involved in creating successful bottle packaging are overlooked.

In this guide, we’ve highlighted the full range of considerations your business should take into account if you want not only to ensure the safe delivery of your bottles but also to provide an experience that delights your customers.

We’ll explore the role of print beyond branding alone, how different materials can influence how your brand is perceived, the growing importance of sustainability, the variety of inserts available, and much more.

Contents

Introduction

Why is bottle packaging important?

Consumer habits are changing, and the move to eCommerce was partly driven by the COVID-19 pandemic and sustained due to convenience, technological advancements, and consumer priorities.

In fact, the IWSR predicts that online sales of alcoholic beverages will increase by up to 66% by 2025.

This is backed up by statistics indicating that whilst eCommerce sales of drinks increased by 12% in 2019 (the last year before the pandemic struck), the figure jumped to 43% amid the lockdowns imposed in 2020.

The role of bottle boxes and shippers

All of this adds up to mean that the role of eCommerce packaging, and bottle boxes in particular, has taken on ever more importance.

As the market matures, however, and brands look to gain a competitive advantage over rivals, packaging is one of the key weapons for attracting and retaining customers.

As such, there are several considerations beyond transit packaging that must be taken into account when sourcing (or improving) your bottle boxes and drink packaging.

These include:

- Using the correct size and format.

- Which inserts (if any) you should use.

- The material grade of your bottle packaging.

- The material appearance and/or colour of your boxes.

- Any inclusion of branding.

- Any additional instructions and information.

- The recyclability of your bottle packs.

- The sustainability of your boxes and overall operations.

The rest of this guide provides further information on each of these key points, helping you leverage your bottle packaging to gain a competitive advantage for your business.

Size and format

How the wrong-sized boxes can cause numerous issues

It is not uncommon for drinks businesses to use cardboard bottle shippers, which are a poor fit for their bottles.

Whilst the majority of wine and beer bottles fall within fairly standard size and shape parameters, the same can’t be said for most spirits. In fact, many manufacturers use unusually shaped bottles as a form of differentiation, and in some cases, even extend their branding.

The problems arise when standard-sized bottle boxes are used to ship these types of bottles.

Packaging that is too small does not allow adequate protection, potentially leading to damage. Boxes which are too large require excess void fill (or other inserts and materials) to prevent movement within the outer box (which can also cause damage). Over-sized boxes also make shipping more expensive and have a negative environmental impact (increasing CO2 emissions due to less efficient shipping).

Besides considering custom-sized bottle boxes, it is also essential to select the correct formats.

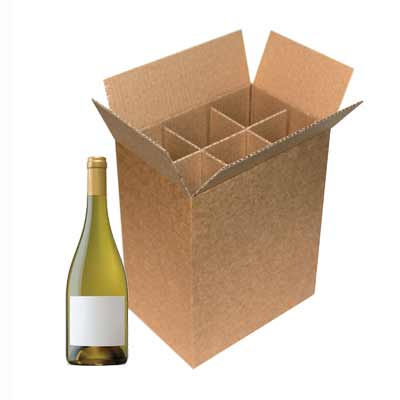

This means your inventory includes both single-bottle shippers and multi-bottle boxes with dividers for shipping larger orders (and for applications such as wholesaling).

Get this first step right, and it can prevent various problems further down the line.

Bottle box inserts

Ensuring adequate protection for your bottles

Although the outer pack will absorb some of the stresses and strains encountered along the supply chain, it is essential to recognise the role that suitable bottle pack inserts can also play.

These can provide additional cushioning protection to absorb shock and impact. Virtually eliminating costly damage.

Saying that, they can also play an essential role in the unboxing experience of your products. Premium corrugated inserts, for example, featuring branding will provide a much more premium feel than bubble wrap or other plastic options.

This point also ties in with ease of use and disposal for your customers, too. Whilst a customer’s minimum expectation is that their orders will arrive intact, any inserts that are difficult to recycle can frustrate and annoy shoppers. It may even discourage them from shopping with you again.

Due to the sheer number of options, it is worth viewing this separate article covering the pros and cons of different insert options.

Material grade

Selecting a material that is appropriate for your requirements

Whilst bottles and their contents can be both fragile and heavy (a relatively unusual combination), one of the great fallacies when selecting suitable packaging is that heavy-duty grades of material are always required.

In fact, working with a suitable packaging designer (rather than purchasing off-the-shelf boxes) can allow for an optimum grade of material to be chosen. One that offers both good protection, ascertained through theoretical data and physical drop tests, and is cost-effective.

Many businesses discover they can switch to a lighter-weight material for their bottle boxes without affecting protection levels.

However, the differences are noticed elsewhere. Most notable is the cost savings, with less materials being used overall, minimised shipping costs (as the material is less bulky) and storage (again due to less bulk).

However, the importance of working with an established and experienced packaging designer for this can’t be stressed enough!

Material colour

How colours and appearance can influence consumer behaviour

Besides the grade of material used for your eCommerce bottle packaging, the actual colour of the boxes can also influence consumer behaviour and perception.

For example, organic and/or environmentally focused brands often perceive a brown Kraft material as reflecting their eco credentials. Conversely, white boxes are typically viewed as a premium option, potentially making them better suited to higher-value products.

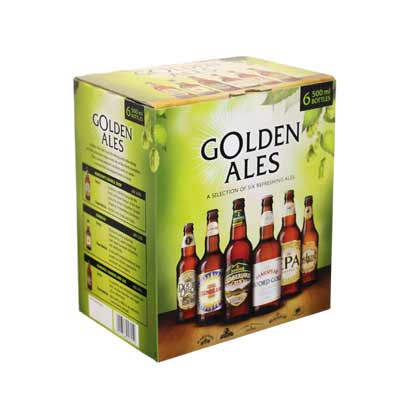

Of course, it is also possible to have your bottle boxes printed with all-over colours to match your branding. However, consideration should be given to whether to print the outside, which provides free advertising but also highlights the contents to potential thieves, or the inside, which enhances security but provides a better unboxing experience.

For something seemingly simple, your choice of material can significantly impact brand perception, not to mention the potential for repeat business.

Bottle box branding

Adding logos and a consistent brand identity

Of course, the colour of your boxes goes hand in hand with how you incorporate your branding.

As mentioned previously, excessively branding the exterior of your packs, especially high-value wines and spirits, can alert potential thieves to the contents of the packaging. It can also make consumers wary if the bottle is being purchased as a surprise gift, as the exterior branding could give away.

Alternatively, inside print means you miss out on any free “advertising” through the supply chain, but it creates a compelling, memorable unboxing experience.

The use of colour is also essential, ensuring that any Pantone references are accurately matched, and that any other graphical elements tie in with the material colour and your overall brand ethos. A good example is the use of white and green inks with brown Kraft material to create a striking appearance that evokes an environmentally friendly aesthetic.

Consistency (across your packaging and other touchpoints, such as emails, eCommerce websites, in-store displays, etc.) and good colour choice can really help drive brand recall, customer loyalty, and repeat sales.

On pack instructions

Improving the usability of your bottle boxes

In addition to printed branding on your bottle packs, it is essential to include instructions and warnings on your boxes.

The obvious example here is to include a “Fragile” warning, so that couriers and delivery drivers will (hopefully) treat the items with greater care. Other symbols highlighting how the boxes should be handled are also a good idea in the vast majority of cases (you can see a range of commonly used transit packaging symbols here).

Also growing in importance is the use of recycling symbols and logos on packaging, providing consumers with instructions on how to recycle their packs. In fact, recent research shows that 58% of consumers look for recycling information when they come to dispose of their packaging, whilst many would make more of an effort to recycle if instructions were clearer.

Including information about recycling also typically helps improve your brand’s perception.

Bottle box recyclability

Helping your customers reduce their environmental impact

Leading directly from the use of recycling symbols on your bottle packaging is the actual recyclability of your packs themselves.

Obviously, using corrugated cardboard outer shippers means your packaging can be easily recycled and manufactured from recyclable materials.

However, the (potential) issues begin when using specific types of inserts.

Again, corrugated dividers, cradles and inserts are all easy to recycle, as are other options such as Flexi Hex. However, many of the plastics and foams used as bottle box inserts are not readily accepted in kerbside recycling schemes. They must be taken to the supermarket collection points or local recycling centres. Both of which are significant barriers to consumers recycling them.

This can again seriously impact your brand’s perception, so caution should be exercised when choosing the most suitable packaging.

Sustainability

A long-term commitment to the environment

Finally, the sustainability of your packaging should be considered.

Whilst many people see recyclability and sustainability as essentially the same thing, there are several crucial differences.

For example, the use of materials from well-managed sources – FSC®-certified packaging being the most obvious example- is becoming a key consideration for many consumers.

Using sustainable materials also allows you to add associated logos and branding (such as FSC® logos) to your packaging, helping with brand perception and repeat business. All this, of course, helps ensure the environmental impact of your business is minimised as much as possible.

Summary

Factors to consider when sourcing bottle boxes

Getting your bottle boxes right can be surprisingly complicated.

This is why it often makes sense to work alongside a packaging designer and manufacturer. Doing so can allow you to source a fully tailored solution that will not only provide protection but also delight (and help retain) your customers.

If you require assistance with your bottle boxes or any other form of eCommerce packaging, why not speak with one of our packaging experts at GWP? We’ll be happy to help you develop the perfect bottle packaging for your specific requirements and applications.

Share this article

Further reading

About the author

Clirenda joined GWP as a structural designer in 2021, bringing extensive experience from roles at SCA Packaging (now Saica) and Smurfit Kappa.

Products in this guide

Get in touch

Related guides

Wine bottle packaging guide – 12 options

Printed eCommerce boxes: Unique branding ideas

11 tips and ideas for successful branded packaging

Using FSC® on packaging (FSC® packaging logo guide)

18 bitesize tips for packing postal orders and eCommerce fulfilment

7 facts on the importance of eCommerce packaging

Analysis: Stock vs. custom eCommerce packaging

eCommerce shipping – the crucial role played by packaging