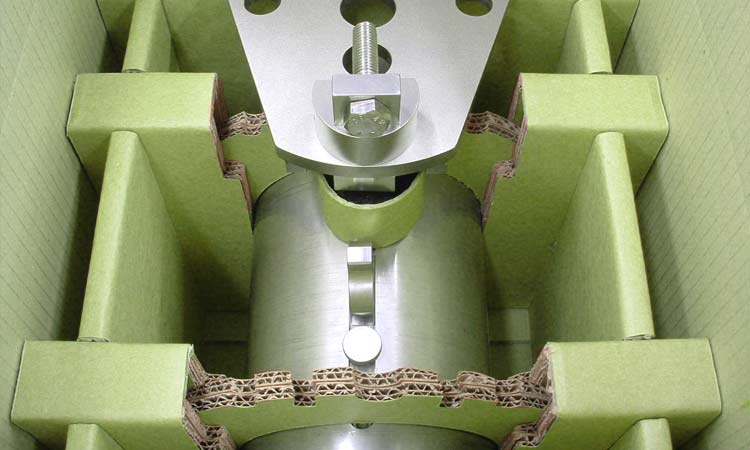

Bio VCI coating for corrugated

If your business or customers ship ferrous metal items, VCI cardboard packaging (volatile corrosion inhibitor) can protect them in transit.

Bio VCI coating for corrugated, when converted into packaging, prevents its contents from rusting. It works by forming a thin, invisible layer of VCI molecules on metal surfaces, inhibiting corrosion caused by atmospheric moisture. Independently tested, Bio VCI is also long-lasting, safe to handle, and easy to recycle.

GWP Coatings can supply UK sheet plants with VCI-treated cardboard and/or converted VCI packaging as part of a confidential trade agreement. Our team of packaging experts can advise on converting the material at your sheet plant or develop a solution tailored to your specific application.

Benefits of Bio VCI cardboard material/packaging

By sourcing Bio VCI-coated cardboard from GWP Coatings, you can expect the following benefits:

Technical and conversion information

Conversion information

Bio VCI coating for cardboard works through VCI molecules vaporise out of the coating and saturating the area within the package.

Due to its polarising character, the molecules attach themselves to the surface of the metal goods, preventing the reaction of oxygen with the metal surface that causes corrosion/rust.

When businesses manufacture new metal products, they can insert them directly into the Bio VCI coated package without needing to apply a corrosion protection material or wrap it in VCI paper. As such, end users can open the package and use the product immediately without needing to remove any protective greases or coatings.

Bio VCI can be applied to either one or both sides of the corrugated board and is clear in colour. You can request the addition of tints for identification.

Bio VCI coating should only be applied to a pure Kraft liner, as recycled liners contain harmful chemicals that can promote rust.

Sheet plants should convert the coated board within 2-3 months of manufacture. It is possible to store it for longer, provided it is fully wrapped with stretch or shrink wrap. If it is left unwrapped, its VCI properties decrease over time.

The minimum sheet size available is 250 x 500 mm, and the maximum sheet size is 1500 x 3000 mm.

The chemicals used in VCI treatment are fully biodegradable and recyclable. They do not use any nitrates, heavy metals, silicon, or other hazardous substances. Packing staff and other users can handle the material without the need for protective clothing.

Limited warranty

All statements, technical information and recommendations are based on tests GWP Coatings/MetPro Group believes to be reliable, but are not guaranteed. GWP Coatings warrants that Bio VCI products will be free from defects when shipped.

GWP Coatings’ obligation under this warranty will be limited to the replacement of the product (coated material or fabricated pack) proven to be defective. To obtain a replacement product under warranty, the customer must notify GWP Coatings of the claimed defect within six months of shipment. The customer will be responsible for all freight charges associated with the replacement.

GWP Coatings has no liability for any injury, loss or damage arising from the use of or the inability to use the products. Before using, the user must determine the suitability of the product for its intended use, and the user assumes all risk and liability whatsoever in connection therewith. No representation or recommendation not contained herein shall have any force or effect unless in a written document signed by an officer of GWP Coatings.

The foregoing warranty is exclusive and in lieu of all other warranties, express, implied or statutory, including without limitation any implied warranty of merchantability or of fitness for a particular purpose, in no case shall GWP Coatings be liable for incidental or consequential damages.

FAQs

What is VCI?

The term VCI stands for Volatile Corrosion Inhibitor. Also known as vapour phase corrosion inhibitors (VpCI), these products protect metal surfaces from rust and corrosion.

How does VCI cardboard work?

Bio VCI technology works through VCI molecules vaporising out of the coating on the board and saturating the area within any assembled packaging. The VCI molecules are drawn out of the coating due to polarisation and attach themselves to the metal surface of any goods inside the packaging. The coating then prevents any reaction with oxygen that would cause rust to appear on metal surfaces.

Is Bio VCI coated cardboard safe to use?

Bio VCI is entirely safe, meaning boards coated with it pose no risk to you or your operatives when handled. This eliminates the need for PPE, saving you the costs of purchasing specialist protective equipment and streamlining operations in your plant.

Is VCI packaging environmentally friendly?

The VCI chemicals used for this coating do not contain any nitrates, heavy metals, silicon or any other potentially dangerous substances. The benefit of this is that the board coated in Bio VCI is biodegradable, recyclable, and poses no threat to the environment. No special measures are required to dispose of unused Bio VCI-coated board, minimising disposal costs and the need for additional storage prior to disposal.

How long do VCI properties last?

Sheet plants should convert board coated with Bio VCI within two to three months of manufacture to ensure maximum benefits of the anti-corrosive elements. However, it can be stored for longer periods provided it is fully wrapped in stretch or shrink wrap.

Disclaimer: Application images on this page may have been enhanced or created specifically to illustrate a products features and/or potential uses. Please see our content policy for further details.

Why GWP Coatings?

Confidential trade supply

We can supply any coated cardboard material you need as part of a confidential agreement, and at competitive trade pricing.

Flexible volumes

We can coat a wide range of corrugated boards – supplied by us or by you – from as little as 200 square meters and typically within 48 hours.

UK-based experts

With over 35 years of experience in coating corrugated board, our UK experts can provide both technical advice and conversion information.

Quality guaranteed

Coating all board in-house enables us to have complete control over quality, guaranteeing exceptional coverage and performance.

Quotes, technical info and advice

Speak with our UK-based coating experts

The information on this page has been collated, checked and approved by several of our corrugated coating experts: