A comprehensive guide to Correx®

What is Correx®?

If your business uses any returnable packaging or even warehouse picking bins, you may have heard of Correx®.

But what exactly is Correx®?

Correx® is a corrugated plastic material that is durable, hardwearing, water-resistant, and available in various grades and colours. Its use is widespread for signage, floor protection, and reusable packaging. The term Correx® is a trademark of Corplex.

In this guide, we’ll provide detailed information on Correx® specifications and properties, the various applications for corrugated plastic, alternative options, and the material’s sustainability.

Contents

Correx® specifications

How is Correx® made?

Essentially, Correx® is corrugated polypropylene plastic. In simple terms, it is produced by pouring melted plastic through a metal template or die.

During the manufacturing process, plastic (propylene-ethylene copolymer) is extruded through a die. Once extruded and allowed to cool, it forms into a long, continuous sheet.

Finally, the manufacturer cuts the sheets into the required size and shape or format.

The result is a two-ply fluted, durable, yet flexible plastic.

What are the specifications of Correx®?

The standard sheet sizes for Correx® boards are 8′ x 4′ (2440mm x 1220mm) or 10′ x 5′ (3050mm x 1550mm).

Correx® sheets are also available in varying thicknesses, including 3mm, 4mm, and 5mm. Many suppliers also detail the material’s GSM (grams per square meter). For example, 3mm Correx® is 450GSM, 4mm is 700GSM, and 5mm is 1050GSM.

These different weights and strengths make Correx® suitable for a wide range of other applications.

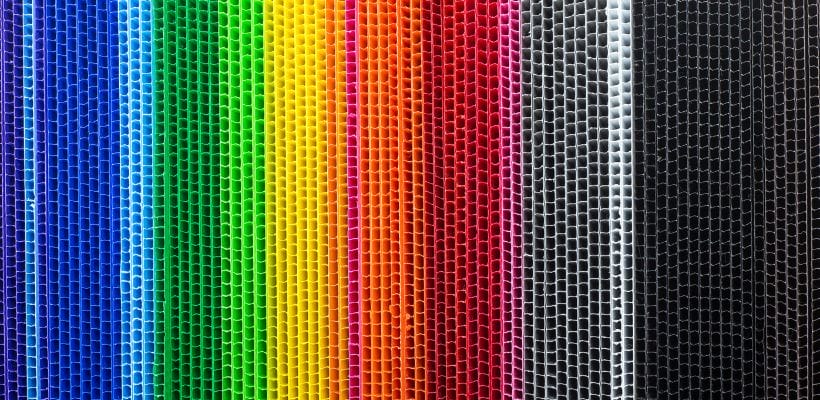

What colours is Correx® available in?

Correx® is available in a range of standard colours.

Options include white, black, red, blue, green, yellow, and grey. It is also possible to source Correx® in transparent.

Where larger volumes of material are required, for example, in the case of long-run printing or some industrial packaging applications, it is possible to specify bespoke colours.

Other specialist options

There are also a few specialist grades of Correx® available.

Firstly, it is possible to source a flame-retardant Correx®. Special additives added during manufacture prevent the material from igniting. Flame-retardant Correx® is popular for floor protection and other construction industry applications.

Secondly, an ESD version of Correx® is also available. This material has carbon added during extrusion. This addition means that the material channels static across its surface. As a result, the material can be used to create a Faraday Cage effect (making it useful as conductive packaging or for cleanroom applications).

Finally, a recycled Correx® is available. This material uses only recycled plastics. Whilst improving sustainability, it is only available in black.

Properties of Correx®

Performance of corrugated plastic

The material and manufacturing process provide Correx® material with many advantageous properties.

It is highly durable, impact-resistant, and has an excellent strength-to-weight ratio. These properties make it ideal for heavy-duty packaging and handling applications.

Besides this, the material is 100% waterproof and weatherproof. As well as enhancing its longevity, these properties have made it popular for external signage and construction projects.

In addition to water, Correx® is also resistant to mould, fungi, and most chemicals.

Temperature and impact performance

Correx® uses an ethylene-propylene copolymer, which is resistant to impact. It exhibits high impact resistance over a wide temperature range, from approximately 0°C to 85°C.

Above 85°C, the material starts to soften, increasing the impact performance whilst losing structural strength. The material continues to soften until approximately 140°C, when the polymer begins to melt.

At temperatures below 0°C, Correx® becomes more rigid but also more brittle.

At -18°C, the impact strength is reduced by approximately 10%. While there are no impact performance measurements below -18°C, other industries routinely use polypropylene copolymers at temperatures down to 30°C (e.g., for ice cream tubs).

Down to temperatures around -30°C, you can expect the structure of Correx® to remain intact so long as the product is not subjected to unreasonable treatment. You can expect Correx® boxes to perform well in an environment such as on shelves, single-stacked.

Full technical characteristics

The detailed performance characteristics of Correx® are as follows:

- Softening temperature (BS2782: 102D ISO 1306) 85°C.

- Crystaline melting point 160-175°C.

- Flash ignition temperature at 350°C.

- Calorific value 11000 cal. Kg.

- Specific heat 0.46 cal/gm°C.

- Limiting oxygen index (ASTM D 2863) 0.174-0.180.

- Burn rate (FMVSS 302) 5.3-8.2cm/min.

Correx® conversion

Making Correx® into useful products

In addition to its beneficial properties, Correx® offers excellent versatility in conversion options. In fact, it is possible to convert Correx® in many of the same ways as with corrugated cardboard.

Die-cutting Correx®

Correx® is easy to convert by die-cutting. This process involves using a sharp steel knife cutting form, similar to a cookie cutter. Specialist equipment compresses the corrugated sheets and cutting form together under high pressure to create the required shape and dimensions.

Die-cutting can also add creases to the material, making assembly easier (e.g., when folding to create a Correx® box or tray). Creasing is where the shape blades do not pierce through the material’s surface but create an impression to aid folding.

However, it is essential to consider flute direction. The material bends easily along with flutes, but folding across the flutes is more difficult.

CAD cutting

CAD cutting is another type of conversion process that works on corrugated plastic. A large machine moves a sharp knife across the material, following a computer programme, to create the required shape.

Additional features

There are several additional features you can choose to add to Correx® products.

Options include moulded plastic handles, stacking corners, and edge profiles. These can be glued onto or screwed into the Correx® material.

Printed Correx®

Branding options for Correx®

Correx® provides a flat, smooth surface that enables high-quality printing. While material allows for an accurate representation of full-colour graphics, the bold hues of the other colour options combine well with single-colour print designs.

Digital print

Correx® is suited to digital printing. This process involves being added directly to the surface of the Correx® material (rather than being transferred from printing plates as per analogue methods).

Digital printing of Correx® allows for full-colour and photographic-quality imagery. As a result, the material is widely used for external signage (most commonly for estate agent signs).

Screen printing

It is also common to print Correx® using screen printing.

This process involves forcing ink through a mesh screen onto the surface. Making certain areas of the screen resistant to printing ink effectively creates a stencil and prevents ink from transferring to the substrate. This, in turn, creates the required design.

Screen printing, however, is only suitable for one- or two-colour designs. As such, this printing method is often used for returnable packaging applications.

Applications of Correx®

What is Correx® used for?

Due to its properties and ease of conversion, corrugated plastic is the material of choice for many applications.

Correx® is widely used for, but not limited to, the following applications:

- Returnable packaging.

- Picking bins for warehouses.

- Point of Sale stands (POS).

- Event shell scheme panelling.

- Floor protection for building sites.

- Specialist projects, including clean rooms and medical storage.

Packaging

Correx® allows for the manufacture of returnable transit packaging.

As well as providing performance approaching that of moulded plastic containers, it can also be used over multiple trips (e.g., as part of a returnable supply chain setup).

Arguably, its main benefit, however, is the size flexibility it offers. Whilst moulded containers are only available in a limited range of sizes, Correx® tote boxes or returnable packs can be manufactured to the exact size that you require.

Custom-sized returnable packaging improves protection (as parts can’t move within the outer container) and warehouse and transport efficiency.

Correx® can even be used to create internal fittings, such as divider sets and layer pads, to further improve usability and protection.

Warehouse management

Corrugated plastic is an ideal material to manufacture warehouse picking bins.

Widely used in 3PL and eCommerce fulfilment, Correx® picking bins enable logical ordering and storage of stock, as well as the “picking” of customer orders.

Similar to returnable packaging, using Correx® for your picking bins lets you source containers in the exact size you require. This approach can help maximise the available space in your warehouse.

Point of Sale (POS)

Point of Sale (POS) is a great marketing and sales opportunity, and choosing Correx® for this offers many benefits. Advantages included supporting the weight of heavier products, being reusable, easy to clean, and being suitable for outside areas (e.g., in DIY warehouses or garden centres).

And, of course, Correx® FSDU (free-standing display units) and POS stands can include full-colour print to ensure accurate branding.

Specialist industries

Correx® is also popular in several specialist applications.

The fact that it is easy to clean, does not shed any fibres and can be sterilised (including EtO, gamma, and autoclave sterilisation) makes Correx® a popular choice for healthcare, medical, and pharmaceutical applications.

Signage

Perhaps the most widespread use of the material, Correx®, is incredibly popular for external signage (most notably estate agency signs).

Correx® is weatherproof and easily printable, making external signage durable and long-lasting even when exposed to the elements.

Construction and floor protection

Corrugated sheeting is popular for protecting finished products, such as walls or floors, on construction sites. This industry may also use Correx® for formwork and shuttering.

Correx® alternatives

Similar brands and names

Correx® itself is a brand name of Corplex. However, several nearly identical materials go by different names.

Other brands and names for the material include Corvex, Corriflute, Corflute, Corriplast, and Twinplast.

However, there are also several alternatives to Correx® for both material and application uses.

Bubble-board

Bubble-board is a three-layer plastic material with an interlinking internal cellular structure. This construction means it exhibits equal rigidity in both dimensions.

However, where it differs from Correx® is the available (optional) laminates that the material offers. Options include a cloth-covered version to prevent scuffs and a foam-laminated version that adds a layer of cushioning and impact protection.

These properties make it particularly suited to creating divider sets and inserts for reusable packaging.

Moulded plastics (e.g., totes and pick bins)

When considering returnable packaging and picking bins, an alternative option is moulded plastic.

Being slightly more durable and longer lasting, moulded bins and containers can also be surprisingly cost-effective.

However, they are only available in a limited range of sizes, which can hinder the efficiency of handling, transport, and even storage.

Heavy-duty corrugated cardboard

Somewhat surprisingly, some heavier grades of corrugated cardboard are a suitable alternative to Correx®.

Heavy-duty double-wall and triple-wall grades (including Tri-Mite) offer strength approaching that of Correx®. They also offer the same size, printing, and conversion flexibility. Crucially, corrugated is considerably easier to recycle and most perceive it as more environmentally friendly than plastics. Corrugated packaging is also not subject to the Plastic Packaging Tax (unlike Correx®).

However, corrugated is typically used only for a single trip (making it more costly over a longer period). It also has little resistance to water, making it unsuitable for long periods exposed to the weather. It also sheds fibres, making it unfit for many cleanroom and precision-engineering applications.

Sustainability

Can you recycle Correx®?

Correx®, as polypropylene plastic, is 100% recyclable. However, it is a level five recyclable material, which is not accepted in UK kerbside recycling bins. As such, Correx® requires specialist recycling facilities.

Although Correx® is technically biodegradable, the process takes many years. The material does not readily decompose or biodegrade, as these processes rely on bacteria to consume and break it down.

To prevent environmental damage and ensure proper disposal, an effective recycling scheme is required.

Summary

Using Correx® at your business

If you are not already using Correx® at your business, there may be significant benefits to doing so.

However, due to the differences in protective performance, longevity, cost, and recyclability, it may not always be a straightforward switch. Saying that, there is a wide range of applications where using Correx® would significantly benefit your business.

At GWP, we are the UK’s leading independent converter of Correx® material. We have over 30 years of experience providing Correx® bins, boxes, totes, and other returnable packaging to a vast range of businesses and industries. Still, crucially, we also offer a range of alternatives (including corrugated cardboard), making us ideally placed to provide you with genuinely impartial advice.

If you would like further information and advice on what Correx® is or how you can use it in your business, please do not hesitate to get in touch with our team of packaging experts.

Share this article

Further reading

About the author

Steve is one of the senior designers at GWP, joining in 2009. Working primarily with Correx, he also has extensive experience of corrugated.

Featured products

Get in touch

Related guides

Moulded vs Correx® vs cardboard K-bins®

17 reasons to switch to returnable transit packaging

Pick bins: 9 considerations when sourcing

7 options and ideas to enhance custom picking bins

The 6 basics of successful order fulfilment

45 bite-size tips for improving warehouse management

21 ways to reduce warehouse picking errors at your business

How to setup and manage a reusable packaging system

Temporary picking bins – 12 ways they help with seasonal demand