Deciding Which Picking Bin

The most suitable option for your specific requirements and applications

You’re ready to take the plunge.

Your inventory has been planned and organised (or re-organised), your picking and packing processes are in place, you have a well-trained team of order pickers, and your marketing team (or perhaps even yourself) are readying the campaigns that are going to start driving increased sales.

But you still need to source your picking bins.

Easy.

But wait. Once you begin looking there is actually a wide range of options. Different materials. Branded items (such as K Bins or Linbins) or custom picking bins. Stacking. Sizes. Colours.

But where do you start?

Quick Reference / Contents

01: Pick Bin Considerations

Considerations when choosing your picking bins

There are actually a huge number of considerations that should be taken into account before deciding which type of picking bin will be most suitable for your business.

For starters, you need to consider your inventory and the types of product or components you will be storing. Obvious factors such as the size, weights and fragility of them, but also the total amount of items, the number of product groupings and the expected stock turnover rate.

Besides this, you need to consider the environment where your picking bins will be placed. Is it a cold, damp warehouse, or heated annexe to your main offices? How much, and what types of space (e.g. racking, shelving, floor etc.) are available?

And, if it is relevant, are there any regulations specific to your industry that may influence the type of material your parts bins should be made from?

02: Picking Bin Types

The 3 picking bin types available

All of this can be distilled down into 3 main choices.

So whilst there is a huge array of specific choices within each of these different types of picking bins, you essentially have one of three choices.

Corrugated cardboard, corrugated plastic (Correx®) or moulded / rigid plastic.

Although commonly used to manufacture packaging and boxes, corrugated cardboard is also widely used to make picking bins too (including the well-known K Bins).

You may not be familiar with the term Correx®, but this is described by some as being “plastic cardboard”. Almost any cardboard product can be made from Correx®, but it is stronger, longer lasting and resistant to water etc.

Finally, moulded or rigid plastic bins are as the name suggests – tough, usually polypropylene material moulded into various shapes and sizes. Popular and well-known brands in this segment include Lin-Bins and SSI Schaefer euro bins.

Which option should you choose though?

The rest of this article sets out the pros and cons of each the 3 options, allowing you to decide which is the most suitable for your specific requirements.

03: Option A

Corrugated Cardboard (e.g. K Bins)

The first option you should consider – and one of the most popular – is corrugated cardboard picking bins. These are quite often referred to as K bins, although other branded and non-branded versions are available.

There are a number of reasons why use of K Bins is so widespread.

Firstly, the cardboard construction makes the bins exceptionally cost effective. This means they are a relatively low investment up front, and if any bins become damaged they are not expensive to replace either.

The corrugated cardboard material also makes them lightweight, meaning they are easy to handle, whilst the nature of their construction means they can be delivered flat (saving on delivery costs), but can also be stored flat when not in use.

This means they are ideal for reacting to seasonal peaks in demand when you may need more capacity for your inventory.

They do have a number of relatively serious drawbacks however.

Firstly, cardboard does not deal with water or moisture particularly well. This means that, depending on your warehouse, they may not be a suitable choice (even condensation can cause them to warp and degrade).

Cardboard is also not as durable as plastic, so if they are being handled frequently they will wear out much more quickly.

One argument is that this is not a problem as they are relatively cheap to replace, but it can mean that the lifetime cost of the bins is actually higher than plastic versions which cost more, but last longer.

Finally, if your cardboard bins become dusty or dirty then it is very impractical – even impossible – to clean them. For industries such as medical or even food, the fibres generated by the bins can also be a problem too.

Corrugated cardboard K Bins summary

- Low cost (to purchase and replace)

- Flat pack, allowing easy storage when not in use

- Lightweight and easy to handle

- Can’t be cleaned if becomes dusty etc.

- Sensitive to moisture and water

- Poor longevity compared with plastics

04: Option B

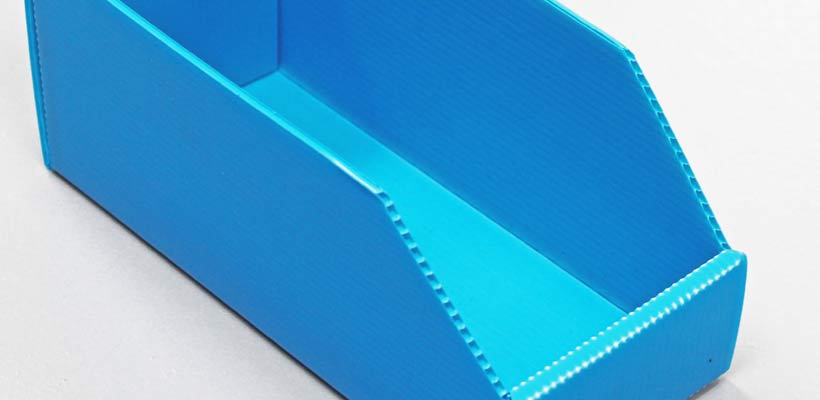

Correx® picking bins

A type of picking bin that has grown hugely in popularity – and is in fact now used in the operations on most well-known “high street” businesses entering e-commerce – is Correx®.

Arguably one of the reasons that Correx® bins are becoming the main choice for large and small operations alike, is that it combines the best elements of both cardboard K bins and moulded lin-bins.

Correx® bins can usually be collapsed in order to store them flat, whilst the material is lightweight like corrugated cardboard but offers much better durability and longevity. This means Correx® bins will last much longer than cardboard equivalents.

This additional durability also means they offer better protection for the items stored in them. They are resistant to water and moisture (meaning they won’t fail or degrade either), and if they become dusty or dirty, they can be easily cleaned.

They are also resistant to most chemicals, and will not shed fibres like cardboard K bins.

Besides this, they can be designed and manufactured to offer strength equivalent to moulded plastic bins, whilst remaining much cheaper. In fact, all of the above combines to ensure that Correx® bins are the most cost-effective option over the long term.

This, when coupled with the fact that they can be manufactured to any shape and size (so can be tailored to your products or available space), makes them an ideal choice for pretty much any market or application.

Correx® picking bins summary:

- Flat pack, allowing easy storage when not in use

- Excellent longevity and durability

- Varying levels of strength, up to moulded performance

- Protection (moisture / chemicals / dust)

- Wide range of customisation options (sizes / colours)

- Best overall lifetime cost

05: Option C

Rigid / Moulded plastic bins

Seen as the premium option – and rightly so – moulded plastic euro bins are both the moist durable and most expensive.

They are particularly well suited to heavy-duty applications (e.g. for industrial parts or components), where there will be very frequent handling, or there is a need to stack the bins. They are the strongest and longest lasting option (although Correx® can run this close), but this is reflected in their higher price points.

However, their key strength also creates a few potential issues.

Being so strong, they are also quite heavy. This makes handling more difficult more difficult for any staff using them.

Being moulded also means that are only a set number of sizes (custom sizes are eye wateringly expensive). Whilst they are usually tailored to standard racking, it may mean you are forced to select the nearest size above your requirement, which can lead to wasted space.

On the subject of wasted space, it is also impossible to store them flat. This means that they take up a lot of space when not in use.

As previously mentioned, they are the most expensive option, although due to their longevity the lifetime cost can be equivalent to Correx® (and may be better than cardboard K bins depending on your application).

However, for almost everyone who does not require a heavy duty solution, moulded plastic bins will probably be over-specified.

Moulded picking bins summary:

- Strongest option for heavy duty applications

- Ideal for very heavy items / stacking

- Limited sizes / styles

- Heavy, reducing ease of handling

- Can’t be stored flat when not in use

- Most expensive upfront cost (but long lifespan)

06: Selecting a Picking Bin

So which do you choose?

The simple way to look at which picking bin you should choose is simple.

If you have a low upfront budget, and your bins will be used fairly lightly, the cardboard K bins could be a good fit.

However, be prepared to potentially replace them often, meaning your longer-term costs are likely to actually be higher.

Correx® bins are the most suitable choice for nearly all applications.

They offer a great balance between cost, protection and lifespan, and the fact that you can specify custom designed bins means that each of these parameters can be tailored to your requirements (along with sizes etc.).

Finally, if you need a really tough, heavy-duty picking solution then moulded bins are probably your best bet. Just be prepared to pay a considerably higher initial price, and live with some of the other minor limitations too.

In Summary

Analysing your picking bin options

If you are still unsure of the best option for your business, however, please do not hesitate to contact a team member at GWP Group, who will be happy to offer advice tailored to your specific circumstances.

Further Reading...

About the Author

Ian heads up GWP Correx®, having outstanding knowledge and understanding of supply chain, reusable packaging & handling products [Read full bio…]

Featured Products

View the products in this guide...

Get in Touch...

We're here to help!

Related Guides

Free PDF Download

10 Ways the Wrong Picking Bins Are Costing You Money

Get your free guide on 10 ways your picking bins could be adding to your costs.

01793 754 444

Mon – Fri 08.00 – 17.00

info@gwp.co.uk

Email a packaging expert