Introduction

Sustainable packaging trends in 2025

If you’re reviewing your packaging options in 2025, you’re not alone. Businesses across the UK are under increasing pressure to reduce waste, reduce their use of plastic, and respond to consumer demand for environmentally responsible packaging options. More than 80% of UK consumers say that they want packaging to be recyclable or reusable, so whether you’re shipping bottles, electronics, or handmade goods, the right solution can make a big difference to your sustainability goals and customer satisfaction.

One name that often comes up in sustainable bottle packaging is Flexi Hex. Made entirely from paper, Flexi Hex is a recyclable and biodegradable sleeve that utilises an expandable honeycomb structure to protect bottles during transit. Its innovative design has made it popular among vineyards, distilleries, and e-commerce businesses seeking a plastic-free solution that still offers strong protection.

But Flexi Hex isn’t your only option. In this guide, we’ll explore how it compares to other eco-friendly packaging solutions so that you can decide what works best for your products and processes.

Contents

What is Flexi Hex and how does it work?

A closer look at the sustainable sleeve made from paper

Flexi hex is a paper-based sleeve that is designed to wrap around bottles and similar products during shipping. Its expandable honeycomb structure provides flexibility to fit different bottle shapes, while also offering strength and resistance to impacts. As it is supplied flat, it occupies very little storage space and is easy to apply during packing. Once your customer receives their order, the Flexi Hex sleeve can be easily recycled with paper and cardboard waste.

Its design helps reduce damage and improve fulfilment efficiency if you’re dealing with a wide range of bottle styles. The material is lightweight, and the structure is visually distinctive, which adds to the unboxing experience.

Flexi Hex works exceptionally well for businesses shipping wine, spirits, oils, or other liquid products in glass containers. However, it may not suit every business model, particularly if you’re shipping large or irregularly shaped products that require cushioning from all sides.

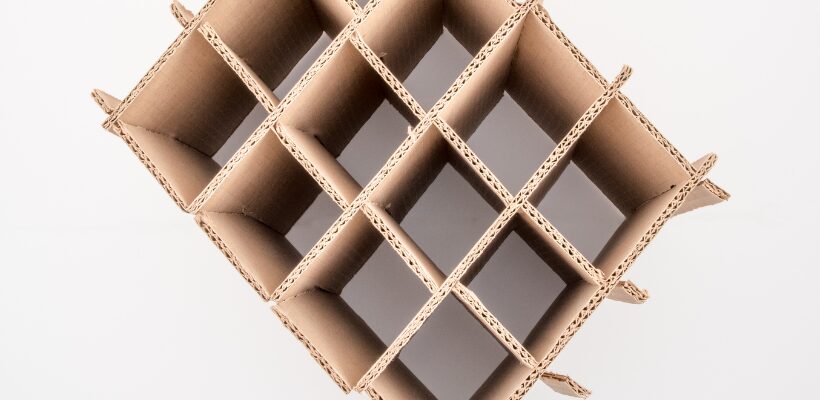

Cardboard dividers and inserts

Simple, recyclable, and widely used

Cardboard dividers are one of the most common forms of protective inner packaging. They work by separating bottles or products within a box to stop them from knocking against each other. They’re often made from recycled materials and are widely accepted in kerbside recycling schemes. In the UK, paper and cardboard packaging have a recycling rate of around 69%, compared to just 44% for plastic.

Compared to Flexi Hex, cardboard inserts are less adaptable to different bottle shapes, and they don’t offer much shock absorption, especially during rough handling and transit. That said, if your bottles fit snugly into the cells and you don’t need extra protection, cardboard dividers can be a cost-effective and sustainable choice.

However, they don’t create the same premium presentation as Flexi Hex, which might be important if you’re trying to deliver a memorable customer experience.

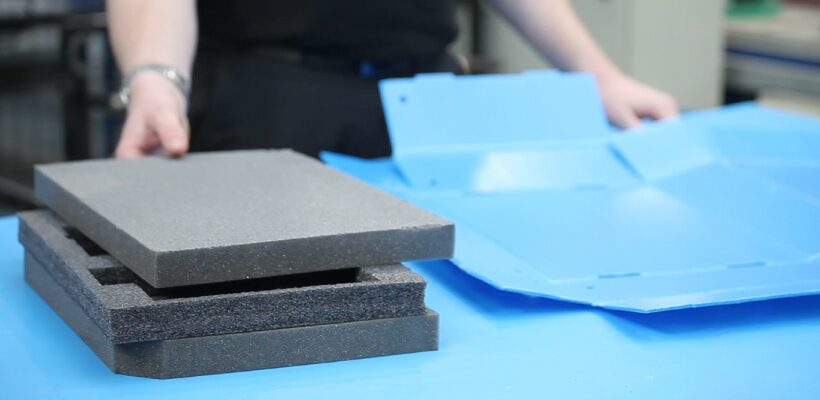

Foam end caps

Maximum protection

Foam end caps are designed to absorb impact and protect fragile items by surrounding them with cushioning. Commonly used materials include Ethafoam and Stratocell foam, both of which are expanded polyethylene foams known for their shock absorption and durability. These foams are often used in electronics and industrial packaging, and are sometimes used in bottle shipping where maximum impact protection is required.

Some grades of Ethafoam and Stratocell foam now include recycled content and can technically be recycled through specialist facilities. However, they are still plastic-based and not accepted in most household recycling collections. This creates challenges for end-users who want easy, responsible disposal. In addition, foam packaging is often bulky and can take up more storage space in your warehouse, which adds logistical complexity.

In contrast, Flexi Hex offers a simpler, more sustainable solution. It’s fully paper-based, kerbside recyclable, and much easier to store and handle. While foam might offer more protection in extreme conditions, Flexi Hex provides a greener, visually appealing alternative that suits many standard shipping needs, particularly for glass bottles.

Moulded pulp

Eco-conscious protection for standardised products

Moulded pulp is created by shaping recycled paper fibres into trays or shells that cradle your product. It has become a popular eco-friendly option due to being compostable, recyclable, and made from widely available materials.

One of the challenges with moulded pulp is the need for tooling, which can add costs if you’re producing short runs or need custom designs. Pulp packaging is also rigid and requires more storage space than flat-packed options, such as Flexi hex. If you’re sending out bottles of various shapes or sizes, pulp might not offer the same flexibility either.

However, for standardised product lines and larger production runs, moulded pulp remains a solid option with strong environmental credentials.

Paper bubble wrap

A lightweight alternative

Paper bubble wrap is made from kraft paper that’s embossed or layered to mimic the cushioning effect of plastic bubble wrap. It’s a versatile solution for wrapping a wide range of items, particularly if you’re seeking something recyclable and biodegradable.

That said, paper bubble wrap usually requires more manual handling during packing. You need to wrap each item individually, which can slow down fulfilment. It also tends to offer less cushioning than Flexi Hex, particularly for heavier or fragile items. If presentation matters, it may also lack the visual impact and structure of Flexi Hex packaging.

Paper void fill

Simple and effective

Paper void fill is often used to fill empty spaces inside a box to stop items from shifting around during transit. It’s a simple solution made from crumpled or shredded paper, and it works well for lighter, non-fragile items.

Compared to Flexi Hex, void fill doesn’t provide direct protection to the item itself. It acts as a buffer within both rather than wrapping around the product. That can be an issue if you’re sending glass bottles or high-value goods that require additional protection. It also usually requires more packaging material overall to achieve the same level of protection.

If you’re aiming to impress with your packaging, void fill also tends to look more functional than premium.

Summary

Finding the right packaging for your products and customers

Choosing the best eco-friendly packaging for your business is more than simply ticking a box; it’s about finding the right balance between protection, cost, storage space, ease of packing, and customer experience.

Flexi Hex packaging is a strong contender, especially if you’re shipping bottles. It protects well, stores flat, looks good, and can be recycled with regular household waste. For other types of products or different fulfilment setups, options like moulded pulp or cardboard inserts might be more appropriate.

At GWP, we understand that one size doesn’t fit all. We work with you to find the right packaging solution based on your products, processes, and sustainability goals. If you’re still deciding between Flexi Hex and other solutions, we can help you compare options and test what fits your business best.

Get in touch with our team of packaging experts today to discuss the best solutions for you.

Share this article

Further reading

About the author

David joined GWP Packaging in 1995. His extensive knowledge and experience of corrugated packaging means he is widely regarded as an expert on this topic.

Products in this guide

Get in touch

Related guides

Wine bottle packaging guide – 12 options

Printed ecommerce boxes: Unique branding ideas

Ecommerce statistics: 200+ online shopping, delivery, and packaging facts/figures

Analysis: Stock vs. custom ecommerce packaging

Ecommerce shipping – the crucial role played by packaging

Corrugated board grades explained: types of cardboard