Automotive supply chain

Why reusable packaging is beneficial for the automotive industry

If your business manufactures or supplies parts to the automotive industry, it is vital that you are aware of the seven important advantages of using automotive returnable packaging.

Returnable automotive packaging includes boxes, crates, containers, inserts, and pallets that can be reused multiple times. Reusable packaging is suitable for storage, handling, and transportation of parts and assemblies and offers numerous benefits. This includes reduced costs, improved protection, and minimised environmental impact.

This guide details all the benefits you can expect from using returnable automotive packaging. It covers:

- Environmental benefits.

- Costs and longevity.

- Usability, compatibility, and consistency.

Contents

Introduction

The history of reusable packaging in automotive

The automotive industry is often credited with inventing reusable containers. Ford Motor Company’s Rouge plant established a container return department as early as 1930, pioneering the use of returnable packaging. They shipped parts in custom-sized boxes, allowing for the reuse of wood in other packaging solutions.

Initially, the primary aim was waste reduction. However, automotive packaging evolved over time into a vital logistical component, enhancing productivity, automation, inventory control, and quality.

By the 1960s and 1970s, the popularity of reusable plastic containers, boxes, and pallets surged. The automotive industry saw the significant positive impact of returnable packaging, which set a precedent for numerous other sectors.

The current automotive returnable packaging market

Starting around 1985, many automotive firms adopted plastic containers and pallets as standard practice. Consequently, the use of single-trip packaging declined, with reusable packaging gaining popularity.

Today, primarily driven by sustainability initiatives and technological advancements, returnable packaging is the norm.

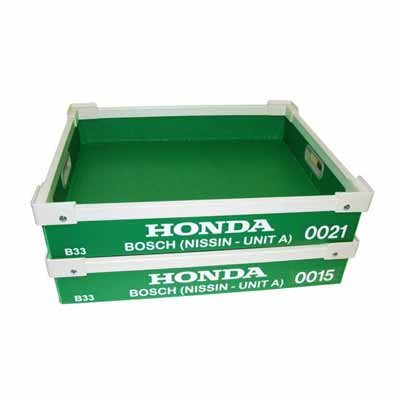

Modern automotive manufacturing relies heavily on a range of reusable products, including Correx® totes, euro containers, pallet boxes, euro pallets (EPAL), KLT containers, ALC (attached lid containers) and Dolavs. This spectrum encompasses both standard and customised packaging solutions tailored to specific component requirements.

7 advantages of automotive returnable packaging

Benefits of reusable packaging in automotive applications

There are seven often-cited advantages of returnable automotive packaging, including:

- Reduced waste compared to single-trip alternatives.

- Enhanced protection for intricate parts.

- Greater durability and longevity

- Compatibility with automated assembly lines.

- Consistent and standardised packaging solutions.

- Typically easier manual handling

- Minimised lifetime costs of packaging.

Minimised waste over single-trip alternatives

Reducing waste compared to single-trip alternatives offers both environmental and economic benefits. Reusable packaging conserves resources, lowers energy consumption, and minimises carbon footprints.

Returnable packaging can also lead to cost savings over time by avoiding the need for continuous purchases of expendable items.

Choosing a returnable packaging solution promotes sustainability, efficiency, and responsible consumption.

Protection for fragile items

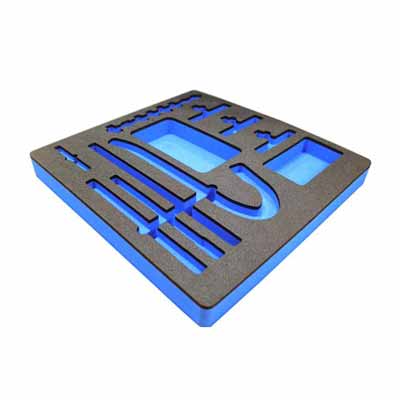

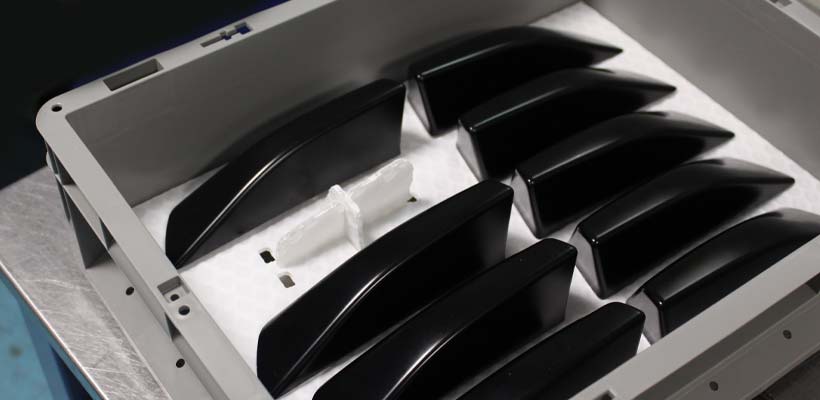

Returnable packaging for automotive parts provides enhanced protection for components through customised fittings, shock absorption materials, and moisture-resistant seals.

Its durability and reusability reduce the risk of damage during transit. This can be critical where a specific volume of damaged components could stop production lines.

Overall, using returnable packaging ensures safer transportation, preserves part quality, and offers long-term cost savings for manufacturers.

Longevity of returnable packaging

The longevity of this type of packaging outweighs the upfront costs. Correx® and similar plastic totes and containers, in particular, can last between 2 and 5 years, depending on the application.

Automation compatibility

This type of packaging is well-suited for automated assembly lines due to its consistent sizing, ergonomic design, and compatibility with RFID/barcode systems.

Its durability ensures reliable performance, while quick return capabilities and seamless integration with material handling systems optimise efficiency.

Using returnable packaging in automated lines enhances productivity, reduces costs, and supports sustainability in automotive manufacturing.

Consistent and standardised solution

Reusable packaging has the added benefit of remaining consistent throughout its lifespan. The durability of a reusable solution means that it can be considered more cost-effective over a longer period of time.

A standardised solution means that any repairs or sourcing of further packaging is simple and with minimal lead times.

Handle with ease

This type of packaging is inherently easy to use. Features like handles and integrated pallets improve handling, whilst printed instructions or symbols (coupled with staff training) can further aid usability.

Lifetime costs of returnable packaging

Returnable automotive packaging has a considerably higher upfront cost than single-trip alternatives. However, based on the number of journeys, the cost per trip soon becomes substantially lower than using expendable packaging.

Factor in reduced breakages, easier handling, and the minimised waste management requirements, and returnable automotive packaging can result in significant savings for your business.

Summary

Securing automotive returnable packaging

Returnable packaging has several inherent benefits for the automotive industry, including reduced costs, improved compatibility, and enhanced part protection. And while sustainability is the biggest challenge facing the industry, implementing a sustainable packaging strategy doesn’t have to be.

At GWP, we have a team of experts with vast experience in maximising the effectiveness of all types of packaging, including optimising reusable and returnable packaging supply chains. We also have extensive knowledge of working with OEM, tier and tier 2 automotive manufacturers.

So, if you would like help with your automotive returnable packaging, please get in touch.

About the author

Ian, as one of the founding Directors of GWP, used his broad knowledge to oversee the new business strategy until his retirement in 2025.

Important note

Due to the regulated nature of the topic this guide addresses (automotive packaging) we have taken extra steps to ensure its accuracy and reliability. You can find out more in our content policy.

All information is, to the best of our knowledge, accurate and correct at the time of publication. Please also note that, as all scenarios vary, not all information contained in this guide may apply to your specific application. There may also be specific regulations or laws, not covered within this particular guide, that apply. Please view the list of automotive packaging regulations for further details.

Share this article

Further reading

Products in this guide

Get in touch

Related guides

How to pack automotive parts – 11 vital considerations

Returnable packaging containers: options and applications

Beginners guide to UN3480, UN3481 and IATA regulations

9 options to enhance supply chain totes & line-side containers

Containers with dividers and other dunnage options for totes

Analysis: Single trip packaging vs returnable packaging

Shipping lithium batteries – Frequently asked questions (FAQs)

How to setup and manage a reusable packaging system

17 reasons to switch to returnable transit packaging

Expendable packaging: 3 real world cost comparisons with reusable