Emily Parker: Last Updated 16th February 2024

Posted In: Efficiency & Productivity | Guides and Advice

A Range of Custom Options to Consider

Choosing the optimum handling totes for your manufacturing setup / supply chain

Whether you are an established manufacturer with a well evolved supply chain and processes, or are only just looking to start sourcing line side containers and / or supply chain totes, one theme is likely to keep cropping up.

Efficiency.

Terms such as “lean manufacturing” and “six sigma” are frequently used by manufacturers, and are seen as a goal to aspire to.

The reason for this? Well, it is due to the fact that these methodologies have been proven to reduce costs and save time on a consistent basis.

Unfortunately, this is rarely easy to achieve. It means examining all aspects of your in plant processes (and supply chain), identifying small areas of improvement on a consistent basis. These small gains can eventually add up to create a significant impact on your business.

And with line side totes or stillages being a key part of your operations (and if they aren’t they should be), the use of these – and the totes themselves – should be optimised as far as possible.

Quick Reference / Contents

08: Attached Lid Containers

09: Colours

10: Printed / branded handling totes

11: Collapsible Totes

12: Find out more

01: Customisation

Why customise your totes / containers?

Consumer choice has created difficulties for manufacturers.

With the expectation of being able to customise virtually all aspects of the goods they purchase – or at least having various choices when buying – the knock on effect has been very specific challenges for companies manufacturing such items.

Buying a car is an oft-cited example.

Just think about how many options you know have when specifying a new vehicle. If you take the dash-board and interior trim alone, the chances are you can choose from a wide range of materials and colours. Grey, black, silver, brushed aluminium, wood veneer, leather and so on.

Going back even as recently as the 1990s, your choices were usually black or black. Now it is often possible to choose between gloss black, anthracite, piano black or carbon fibre, in addition to various other colours.

Effectively, the choices open to modern consumers are huge and varied.

What this means is that both storage of inventory, movement of parts and components and storage when line side needs to be optimised as much as possible to maintain efficiency.

This is where using totes and containers that are easy to use, maximise space, aid productivity and still protect your parts and components, can become crucial.

02: Your Options

The 9 options you can utilise to enhance your supply chain containers

So, when facing such challenges (which applies to varying degrees to virtually any manufacturer), how exactly can totes help?

Well, by sourcing a tote that is tailored to your specific working practices, environment, parts and components, it is possible to maintain and even improve manufacturing productivity and efficiency.

But what are the customisation options for line side containers (which can, also, be used when considering multi-trip packaging)?

The nine most common options are as follows:

- Custom Sizes

- Strength / Material thickness

- Anti-Static / Specialist properties

- Handles

- Lids

- Internal dividers

- Colours

- Collapsible

Please continue reading below for further details on these enhancements, and how they can be used to aid your manufacturing operations.

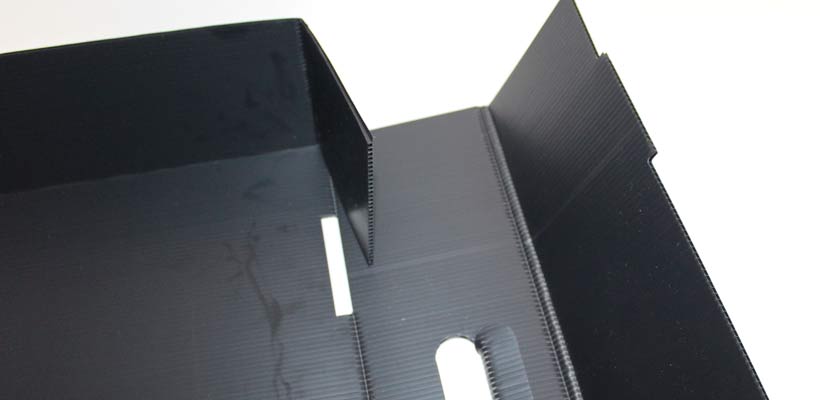

03: Sizes

Custom Size Tote Containers

Starting with the obvious – but surprisingly frequently overlooked – is choosing a custom size for your tote.

Whilst this is not feasible with a moulded plastic tote such as Euro Container (unless you are planning on ordering hundreds of thousands), taking advantage of Correx® can allow you to specify totes to very specific sizes and shapes.

But why would you do this?

Usually, the answer lies in making efficient use of space. For example, if there is a large amount of empty space left in the tote, even when as many components as possible have been put inside, this is effectively wasting space on your factory floor.

It also makes transportation less efficient. If being handled manually, your staff are being paid to transport this empty space (and the tote itself is also likely to be heavier), whilst if the container will be placed in transit between manufacturing centres in your supply chain, the volumetric shipping charges you incur will also be higher.

If you have particularly large components, parts or products, or they are an unusual shape, then it may simply not be possible to find a line side or handling tote that is the correct size.

Effectively, using a custom sized line side tote enables you to make the movement of parts, storage by the side of the production line and transit between sites as efficient as possible.

This, in turn, reduces your costs and enables greater capacity (i.e. more different components can be stored together for easy retrieval).

04: Material

Strength / Material thickness

Although there is some choice in terms of strength options within moulded line side containers, being able to specify specific strengths and durability again tends to be mainly when using Correx® totes.

However, rather than optimising space and efficiency as with utilising custom sizes, taking advantage of different material strengths allows you to cost optimise your containers whilst making sure they are fit for purpose.

For example, if you are handling heavy parts or components, then a strong durable material will be required. Whilst this will obviously cost more in the short term, it will ensure that not only are the parts sufficiently protected, but that the totes offer a higher level of longevity. It also improves the safety of handling too.

All of this actually means that you would end up with suitable totes that offer a lower lifetime cost than if you had to frequently repair or replace under specified ones.

The opposite of this is also true however.

If you are only using or handling lightweight parts and containers then using a heavy duty tote would not be the most cost effective option (a lighter material grade would provide the suitable performance at a lower cost).

Ultimately, it is important to ensure that the line side containers you choose are suitable for the specific applications, environment and industry they will be used for.

05: Anti-Static

Anti Static / Specialist properties

Similarly to selecting a tote that is robust enough for the application it is to be used for, it is important to consider any other properties that may be required as well.

For example, if you are handling or transporting electronic components or parts (such as microchips, circuit boards or assemblies), then these can be prone to damage from static. This, in turn, can lead to components – or the finished products – being rejected or returned as faulty (with the associated costs incurred too).

The solution to this is using conductive or anti-static totes.

These can channel static around the outside of the container, keeping the contents safe.

However, it is not just conductive properties that your totes can be enhanced with.

There are flame resistant grades of material (useful if parts may be stored near sources of ignition for example), as well as VCI corrosion inhibitors (to prevent rust to metal parts in storage / transit).

The benefit of using totes with these properties is that it enhances the protection afforded to the contents, therefore reducing “written off” damaged parts and faulty products and in turn reducing your costs associated with these issues.

06: Divisions

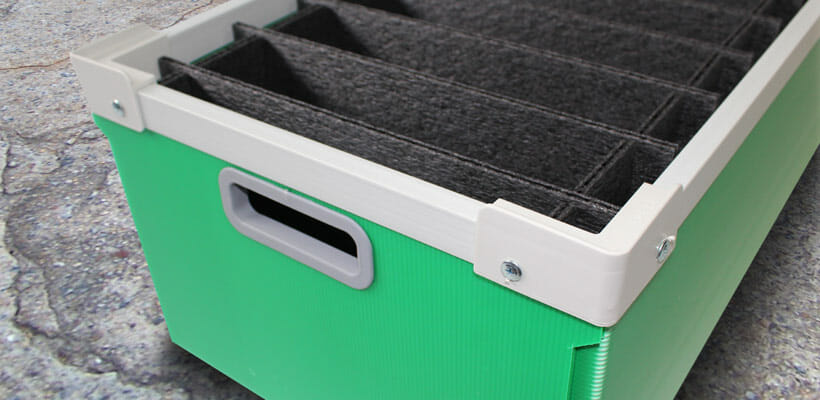

Internal tote dividers

When talking about reducing damage to components and parts when stored or handled within a container, it is important to talk about dividers and inserts.

Manufactured from a range of materials such as cardboard, Correx® or foam (depending on the application), they protect the parts stored within them by minimising movement within the tote. This not only stops them colliding with the walls of the container but also each other.

Specialist materials can again be used to protect surface finishes and delicate parts too.

However, using dunnage also offers productivity gains too.

They allow for the maximum amount of items possible to be safely stored and moved in a specific container. They also allow for much quicker retrieval from the tote and enable quick visual checking of stock (preventing delays if a particular component is allowed to run out).

There are in fact a surprisingly wide range of tote insert options, each with their own benefits and limitations. As such, for further information please read this specific guide on container dividers for further information.

07: Tote Handles

Improve handling and safety

Easy and efficient movement of parts obviously has an impact on productivity (simply through less time handling / transporting them around your factory).

This is why it is nearly always important to consider the inclusion (and type) of handles.

Besides enabling easier movement, this can also aid health and safety, meaning that employees are less likely to be hurt through accidents or poor handling practices, and therefore less likely to be absent.

Moulded totes will usually offer integrated handles, whilst custom totes offer a selection of different styles and sizes which can be matched to the size / weight of the loaded tote as required.

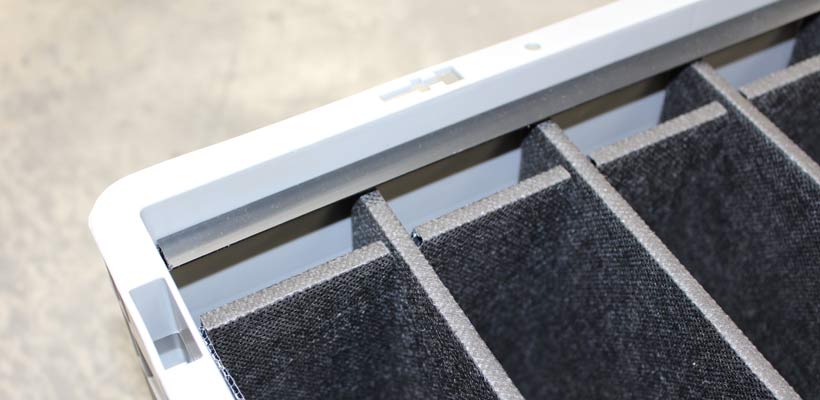

08: Lids

Attached Lid Containers

Although left until quite late in this list, lids are actually a very important consideration for a number of reasons.

Attached lid containers (often referred to as ALCs due to their widespread use) protect the items within from dust and debris getting to them, and if airtight can also protect against moisture and water (particularly useful if part of the supply chain packaging that may be exposed to the elements).

A slightly less obvious benefit is that using lids can also stop staff from overloading totes (as the lids not shutting indicates the tote is too full), helping with health and safety and also eliminating the risk of damage to the components or totes themselves.

There are various lid options (including hinged, clip on and fully integrated, among many others), all of which can aid protection and / or security.

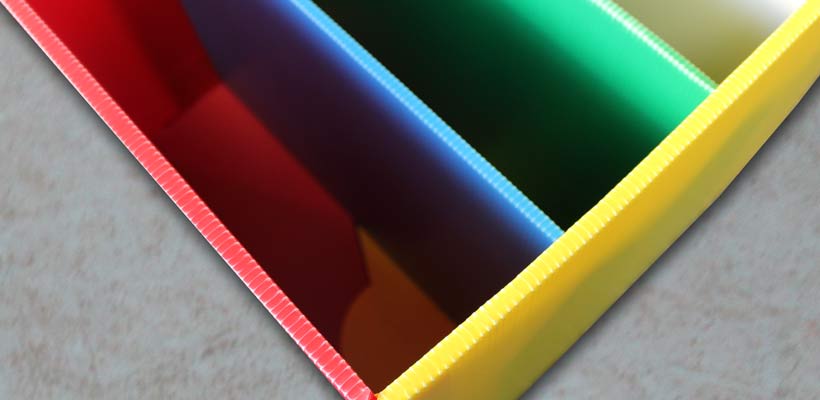

09: Colours

Branding and segmentation

Whilst many companies will specify totes based on their brand colours (which admittedly is a very sensible thing to do), colour can also play an important part in productivity too.

For example, different colour totes can be used to differentiate between similar looking parts or components much more easily / quickly than reading labels etc.

Colours could also be used to distinguish between batches, manufacturing dates (if this is important) and other critical information which needs to be conveyed quickly and easil

10: Print

Branding and segmentation

Used either alongside different colours of totes (or instead of if this isn’t practical), printing the outside of the totes with specific information can be equally useful in helping to identify specific items, batches or products.

However, it is important to consider that printing batch numbers on totes may not be as cost effective as using labels or other forms of marking, and could potentially render the totes obsolete in the future (depending on your identification system).

Having your totes printed with company branding also has a couple of other benefits.

Firstly, it acts as free advertising for your business particularly useful if the items are travelling between sites), and secondly, if being used as part of a wider supply chain it can help in reducing the number of totes that are stolen for use elsewhere.

11: Collapsible Totes

Space saving designs

Finally, a feature which is again often overlooked but can make a surprising difference to cost is whether your line side containers can be folded flat when not in use.

If you have a large number of totes at any time which are not in use (which may be a legitimate requirement due to fluctuations in demand or the nature of your supply chain), then totes which need to be stored can take up a large amount of warehouse space.

This, in turn, incurs costs, and also limits the expansion of other areas (e.g. more production space, or storage for components or finished products).

Correx® totes can, depending on the design, be folded flat when not in use to mitigate this issue.

A lesser – but still valid – benefit, is that upfront delivery costs would also be much lower too.

In Summary

See the benefits of enhancing your line-side containers?

Choosing the right tote or lineside container can be daunting – especially when there are so many options to choose from.

However, with careful thought on how and where the totes will be used, and the areas of your handling or supply chain you feel you need to improve, you can source a container that is an appropriate size, has suitable dividers and a number of other features that can drive efficiency in your business.

If you need any further advice or guidance on the best option for your specific application, then please do not hesitate to contact an adviser at GWP who will be happy to help with your requirement.

Further Reading...

About the Author

Emily, an expert in anti-static and returnable packaging, joined GWP Group – and the fledgeling GWP Correx® division – in 2014. [Read full bio…]

Featured Products

View the products in this guide...

Get in Touch...

We're here to help!

Related Guides

Free PDF Download

21 Point Checklist for Successfully Sourcing Totes

Get your free guide detailing the 21 crucial points to consider when sourcing handling and / or supply chain totes.

01793 754 444

Mon – Fri 08.00 – 17.00

info@gwp.co.uk

Email a packaging expert