Corstat ESD coating for corrugated

Standard cardboard is not anti-static (or conductive), so if you need to offer this type of packaging to your customers, Corstat coated ESD cardboard is essential.

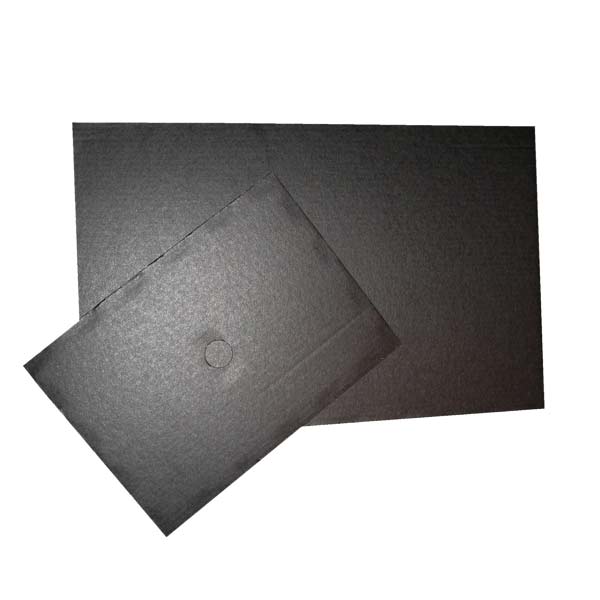

Corstat ESD (electrostatic discharge) coating for corrugated is the industry standard for creating static-safe packaging. These ESD cardboard sheets provide a buried shielding layer to create a Faraday Cage effect. This property protects electronics and static-sensitive items by providing a controlled path to ground for static charges. It is also safe to handle, easily converted, and fully recyclable.

GWP is the sole manufacturer of Corstat coated board and products in the UK, allowing you to source ESD cardboard to convert at your sheet plant and a vast range of stock ESD cardboard boxes. Both options have lead times within 48 hours, flexible volumes, and are available as part of a confidential trade service.

Benefits of Corstat coated ESD cardboard

Corstat coated cardboard offers you the following benefits:

Technical and conversion information

Electrical

Surface Resistivity (per ASTM D257-78)

Buried Shielding Layer <104 ohms/sq.

Exterior Layer <105 ohms/sq.

Electrostatic Decay Rate (per Mil B 81705B, Test Method 4046

Federal TMS 101B)

Less than 2.0 seconds to theoretical zero

ESD Shielding: 99.9% Attenuation (Capacitive Probe Test)

Triboelectric Charge Generation approximately 0.1 C/inch std. condition

Mechanical

Liner papers 100% pure kraft

Shelf Life 10 years

Humidity Dependence: No effect on electrical properties

Chemical

Reducible Sulphur: .00035% (.0008% non-tarnishing to silver, solder, and copper per TAPPI T-406)

Amines: None

Galvanic Reaction: None

FAQs

What is ESD cardboard?

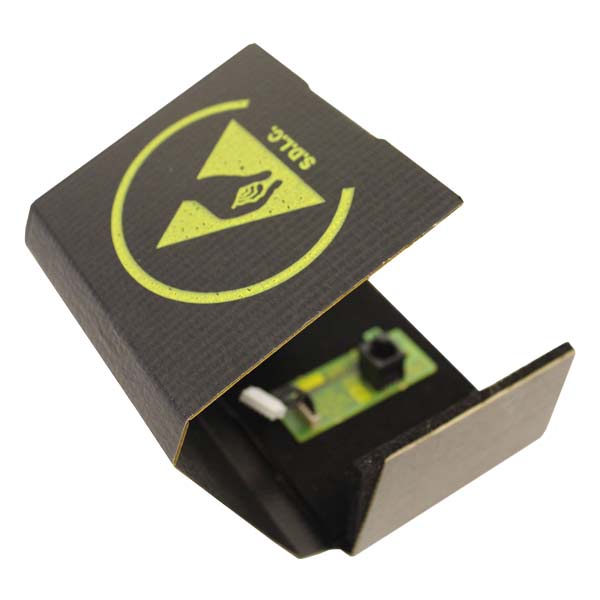

ESD cardboard is basically corrugated fibreboard with a carbon coating. Corstat, the most popular type of ESD cardboard, is commonly used to create long-lasting, durable, and reliable anti-static boxes and packaging for delicate components and any item at risk from static electricity (e.g. microchips, PCBs, electronics, specialist tools and equipment, etc.).

How does Corstat work?

Used by the majority of large electronic companies in the USA and UK, Corstat black conductive cardboard can form packaging that creates a Faraday cage, protecting the items within. This property results in any static charges being channelled around the packs’ exterior, creating a safe path to ground. The obvious benefit provided by these properties is a significant reduction in items damaged during transit or storage, which can in turn lead to substantial cost savings.

What is ESD?

ESD stands for “Electrostatic Discharge”. ESD is the sudden flow of electricity between two electrically charged objects caused by contact, an electrical short or dielectric breakdown. In the industry, ESD can cause significant and costly damage to sensitive items, such as electronics.

Can I purchase ready-made Corstat packaging or boxes?

Whilst GWP Coatings typically supplies sheets or corrugated material coated with Corstat (or other coatings) for use by sheet plants, it is also possible to source a wide range of anti-static boxes, totes, dividers, and other static-safe handling products. These, like the coated ESD cardboard material, can be supplied as part of a confidential trade agreement.

Is Corstat safe to use?

Corstat coating and any products fabricated from it are completely safe and inert. As such, any anti-static packaging made from this material can be handled without the need for PPE, although the product should not be ingested. It is also safe for Corstat® to be disposed of or recycled as per standard cardboard material, and is completely biodegradable.

Disclaimer: Application images on this page may have been enhanced or created specifically to illustrate a products features and/or potential uses. Please see our content policy for further details.

Why GWP Coatings?

Confidential trade supply

We can supply any coated cardboard material you need as part of a confidential agreement, and at competitive trade pricing.

Flexible volumes

We can coat a wide range of corrugated boards – supplied by us or by you – from as little as 200 square meters and typically within 48 hours.

UK-based experts

With over 35 years of experience in coating corrugated board, our UK experts can provide both technical advice and conversion information.

Quality guaranteed

Coating all board in-house enables us to have complete control over quality, guaranteeing exceptional coverage and performance.

Quotes, technical info and advice

Speak with our UK-based coating experts

The information on this page has been collated, checked and approved by several of our corrugated coating experts: