Laminated box dividers

If you need to protect surface finishes during transport and handling processes, textile dividers are the perfect solution.

Textile dividers are a type of laminated box divider. Similar to Correx® dividers, they feature fabric material laminated to their surfaces. Laminated dividers prevent delicate, high-quality, or automotive parts from scratches, marring and cosmetic damage caused by handling, transit vibrations, and packing/unpacking processes.

At GWP Correx®, we are one of the few UK manufacturers to use Bubbleboard material to create textile dunnage and dividers. As with the corrugated plastic dividers we produce, our expert team and in-house manufacturing allow us to customise the size and configuration of your textile dividers to suit your application perfectly.

Please note: Correx® is a registered and/or unregistered trademark of Corplex Plastics UK Ltd, its parent, subsidiaries and/or affiliates.

Benefits of textile dividers

By using textile dividers at your business, you can expect several benefits:

What our customers say...

We previously used cardboard but needed something more robust and with better performance around water. Lead time and price were both excellent. The team and service was quick, reliable, helpful and friendly.

Danielle Roach | Latis Scientific

We have stayed with GWP because the service is so good. The team is friendly, hold the items needed in stock and the pricing is competitive. We buy thousands of boxes each year, plus foam and division sets.

John Wayman | Managing Director | Bondline

GWP really helped us out. They quickly came up with a simple but very effective Correx solution. We’re very pleased with the outcome and we had quite a fun and successful team building hour putting them all together!

Paul Wilson | Project Manager | Heathrow Terminal 2

Material information

Material options

Standard material

This material is not laminated, offering no additional properties.

Anti-scuff material

This material features a laminate on both sides (70 gsm spunbond) to provide anti-scuff properties.

Additional details

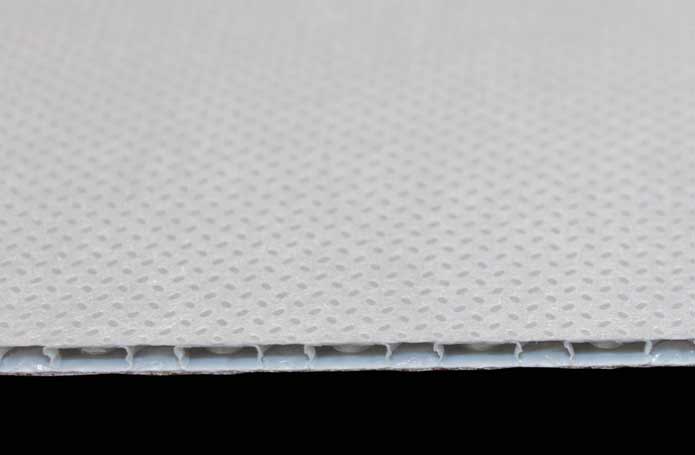

Bubbleboard consists of three layers joined in a unique cellular structure to create a sheet material that is equally rigid in both dimensions.

The surfaces can also be over-laminated to provide additional properties and performance benefits.

The most common of these is the use of textiles, with various nonwoven or spun-bound fabrics applied to one or both outer surfaces.

The fabric covering ensures that any items with highly polished, painted or decorated surfaces are not damaged, scuffed or scratched during storage or transit.

FAQs

What are textile- or fabric-laminated dividers?

Fabric-laminated dividers are plastic sheets comprising two outer layers and a “cellular core” with 70 gsm spun-bond fabric laminated to the surfaces. This material prevents scratches, marring, or blemishes on delicate surfaces – including painted or polished – during handling.

What are textile dividers used for?

Fabric-covered dividers made from Bubbleboard help prevent scuffing and marking on the surfaces of stored or transported items. These properties make them very useful for handling precision instruments, components, and even high-quality consumer goods during manufacture, storage and transportation.

Is the laminated material suitable for other applications?

You can use the Bubble board material used to produce the textile dividers for various other applications. It is commonly used for layer pads and slip sheets and is even suitable for some types of finished packaging.

Will textile divider sets fit my existing containers?

Although available in standard sizes, GWP typically manufactures your textile division sets to your required specification. You can choose the overall size, the number, size, and configuration of the cells, division height, surface laminates, and several other options. This flexibility ensures you can perfectly tailor your dividers to your specific application and requirements.

Is it possible to source dividers and tote boxes together?

By working with GWP Correx®, you can simultaneously source your outer handling containers and any textile dividers or other inserts. Doing so reduces your costs and admin while also guaranteeing a better fit and compatibility than ordering them separately or from different suppliers.

Why GWP Correx®?

20+ years of experience

Having designed container inserts, dividers and fittings for over 20 years, we are now the UK’s largest independent converter (by volume of material).

UK Correx® experts

We have a dedicated team of experts who focus solely on Correx, each with specific, detailed knowledge of the material and its applications.

Competitive advantage

Whether you need to reduce costs, enhance your efficiency, minimise transport, improve sustainability, or something else – we can help.

A business you can trust

Although continuing to operate as an independent business, GWP Correx® is now part of Macfarlane Group PLC – the UK’s largest packaging distributor.

Disclaimer: Application images on this page may have been enhanced or created specifically to illustrate a products features and/or potential uses. Please see our content policy for further details.

Quotes, technical info and advice

Speak with our UK-based Correx® experts

The information on this page has been collated, checked and approved by several of our Correx® packaging experts: