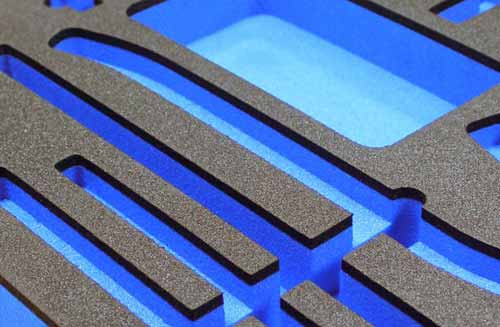

Custom ESD foam for electronics

If you ship parts, components or products that are susceptible to ESD (electrostatic discharge) or physical damage (or both), using anti-static foam can be crucial in protecting them.

GWP Conductive have been designing and manufacturing custom ESD foam for electronics for more than 30 years.

Our expert team has specific knowledge and experience of the nuances of ESD packaging, creating solutions that not only protect your products but also improve packing times, reduce material use, and minimise your costs. We complement this expertise with a vast range of industry-standard conductive boxes, bins and containers, all of which you can opt to enhance with tailored anti-static foam inserts.

Our ESD foam options

Benefits of custom ESD foam

By working with GWP Conductive to source your ESD foam, you can expect:

What our customers say...

We can highly recommend GWP and the Corstat conductive products. As a company specialized in ESD and conductive products, we’ve been working closely together with GWP for more than 20 years. What sets them apart to other companies is the way they work with special customer needs and custom products. The friendly staff members always have a professional approach. In addition, in the rare case that a problem arises, we know we can count on a quick solution without a doubt.

Google review

Great supplier and good service. Would recommend these to any company/customer that requires conductive materials.

James Arran | Lead Estimator | Suttons Performance Packaging

Professional and great company to work with.

Claire Khan | Buyer | Conro Electronics

FAQs

What types of anti-static foam are there?

There are several anti-static foam packaging options, each with slightly different properties and performance. Commonly used materials include pink anti-static foam, conductive Plastazote®, static dissipative, and specialist grades of Ethafoam.

Do ESD foams also provide physical protection?

Besides helping prevent ESD damage to static-sensitive items, custom ESD foam inserts also provide cushioning protection. They can absorb shock and impact caused by mishandling and can even be designed with the optimum amount and type of material to give precisely calculated protection.

Is anti-static foam typically included with ESD packaging?

Almost all of the ESD safe packaging and handling products manufactured by GWP Conductive can have foam inserts added as required. The addition of foam can cover everything from foam blocks and pads to routed foam inserts with contours that exactly match the shape of your products.

How are ESD foam products manufactured?

There are several ways packaging manufacturers can convert anti-static foam. Processes include die cutting, CNC routing and even waterjet cutting. GWP has an impressive, state-of-the-art foam conversion facility in Salisbury, Wiltshire, alongside an experienced, knowledgeable design team.

Is non-conductive foam available?

GWP Protective are one of the UK’s largest independent foam converters. As a result, not only can your business source anti-static foam products, but also inserts for cases, foam end caps, and even retail display items. All of the foam inserts GWP supplies are precisely tailored to your specific application and requirements.

Guides, articles and further reading:

Why work with GWP Conductive?

Whilst anyone can line a box with foam or create some inserts, knowing the intricacies of the material, how it behaves, and the optimum grade and amount required to provide optimal protection applies to only a handful of companies.

At GWP Group, we have been supplying businesses like yours with high-performance, commercially successful ESD foam packaging solutions for well over three decades. As such, you can be certain that any anti-static foam you source from us not only protects against static but also provides a bespoke level of physical protection.

Coupled with the ability to source your exterior boxes, totes, and packaging from a single supplier, if you need conductive foam of any description, GWP should be your first port of call.

Disclaimer: Application images on this page may have been enhanced or created specifically to illustrate a products features and/or potential uses. Please see our content policy for further details.

Quotes, technical info and advice

Speak with our conductive packaging experts

The information on this page has been collated, checked and approved by several of our conductive packaging experts: