Introduction

Helping Swindon Foodbank with efficiency, costs and safety

Swindon Foodbank, a charity based in Swindon, contacted GWP Packaging to explore the possibility of assistance with the packaging used at their distribution centres. Relying on donated boxes, typically of different sizes and strengths, the charity found it difficult to stack, organise and handle food donations. Boxes also lasted a matter of weeks before failing, often damaging food produce in the process.

Rather than simply engaging in a standard design process, however, GWP’s design team reached out to Swindon College engineering students, holding a competition for them to create a solution.

Contents

About the customer

Swindon Foodbank (The Trussell Trust)

The Swindon Foodbank charity launched in 2005 to offer practical help to those facing sudden crisis. Working together with the borough’s support agencies and local volunteers and supported by the generosity of local people, the charity makes a significant difference to the lives of thousands.

Swindon Foodbank is part of the larger Foodbank network, run by The Trussell Trust based in Salisbury. The Trussell Trust is a Christian charity specialising in the development of life-changing community projects.

The Swindon Foodbank shut down in 2019, but was replaced by The Swindon Food Collective, an independent charity providing the same support for those suffering from financial hardship and finding it challenging to provide food for themselves.

The challenge

Problems Swindon Foodbank had with their packaging

Lee Thompson, Project Manager for Swindon Foodbank, approached GWP for help with the packaging the charity was using.

Initial discussions highlighted that their distribution centres, based in several locations around the town, were using donated second-hand boxes to transport produce within their warehouses, vans and distribution points.

Foodbank staff and volunteers often found it challenging to use the inappropriate and second-hand packaging, which, having not been designed for the purpose for which the charity was using it, frequently became damaged. The damage, in turn, often led to food spillages and wastage. The usable lifespan of the boxes was also very short.

GWP also discovered that the boxes, which were frequently different sizes, were impossible to stack safely or efficiently, and made identifying the contents challenging for volunteers as well.

Finally, the Swindon Foodbank also highlighted a continual need to raise awareness and engage the wider community to support its fundraising activities and donations.

The solution

A different approach to problem-solving

A typical project like this would involve GWP’s design team, led by Mike Poynter, creating designs for testing before full production runs. However, on this occasion, the team spotted the opportunity to take a different approach.

Intending to engage the community and raise the charity’s profile, GWP approached engineering tutors at Swindon College to propose a competition among students to design a new concept for the Foodbank.

As a result, GWP’s designers, working closely with the Foodbank, created a detailed brief for the students that would still allow them the opportunity for creative and unique thinking. GWP also offered a monetary prize and a work placement for the winners.

Following several sessions where GWP designers mentored students, including a visit to GWP’s manufacturing site in Cricklade, a thorough judging process selected the winning design. The winning pack, a corrugated cardboard tray, was put into production at GWP before being donated to the Foodbank.

The results

How Swindon Foodbank benefited from the project

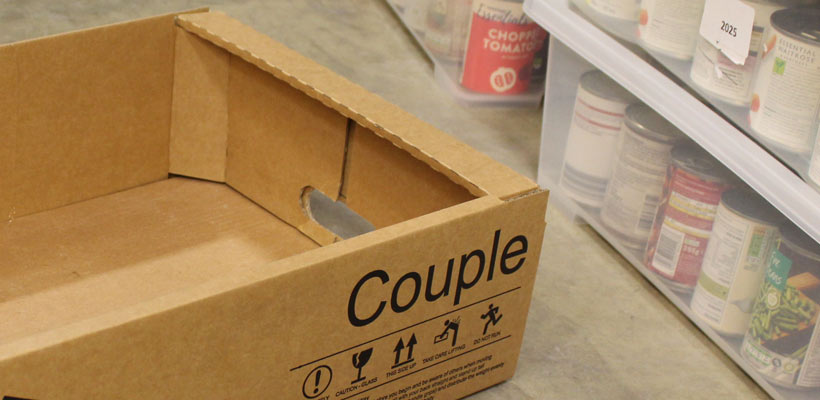

The winning design, taking the form of an open-top cardboard tray, provided several quantifiable benefits for the Swindon Foodbank.

Firstly, the corrugated trays utilise a sturdy, double-walled material. However, to ensure enough strength to handle the contents of up to 16kg, a removable cardboard layer pad was also added to the base of the tray. This design and material choice meant that rather than lasting eight weeks at best, the trays lasted up to two years before needing replacement – an improvement of 1200%!

The hand holes also made it much easier for volunteers to carry food, while the design of the trays – with the material folding over to create an extra-large surface area at the sides and corners – also allowed users to stack the trays up to six high.

Another key benefit was the addition of printing to the outside of the trays. Large print indicated whether the tray contained food for a single person, a couple, or a family, with different coloured text also helping volunteers differentiate at a glance. Essential health and safety information, as well as Foodbank branding, were also added.

Finally, engaging with students also helped raise the charity’s profile, with coverage of the competition and donation of the trays appearing in local newspapers and featuring on BBC Radio. You can listen to the interviews and coverage here.

Customer feedback

Swindon Foodbank comments and feedback

Lee Thompson, Project Manager at Swindon Foodbank, commented:

I’m delighted with how the final designs turned out. Not only do we have packaging trays that significantly improve the efficiency of our operations, but they look great, too. It has been great to get students involved, with the hard work and creativity on display being really impressive. Finally, I’d like to say a huge thank you to GWP for helping the students come up with such a great design, and then manufacturing and donating the boxes to us.

With a focus on student and community engagement, the competition element amongst the college students also proved a great success.

Will Weatherall, tutor at Swindon College, said;

This competition has been a great opportunity for the students who have clearly learnt a lot about the principles of packaging design and have come up with some innovative ideas. It was a great experience for them and gave them a taste of working in the real world. The packaging design workshop that GWP gave them was excellent, and the factory tour was really interesting. They found it especially useful to meet the packaging designers and see how ideas are turned into prototypes. This has been a really valuable experience for all of them.

Summary

Improve your efficiency, safety and more

The unique approach to this problem not only helped students with a real-world challenge, but also had significant benefits to the Swindon Foodbank (not least increased efficiency, lifespan, ease of use and safety).

If you would like our team of packaging experts to devise a genuinely innovative and creative solution to help your business, please get in touch.

Share this article

Further reading

About the author

Mike is an award-winning corrugated packaging designer. Joining GWP in 1995, he oversees the design department in his role as Design Manager.