Introduction

Protecting The Red Arrows vital equipment

The Red Arrows, the well-known aerobatic team, contacted GWP Protective to help them protect the specialist helmets and uniforms that pilots use during their displays. The bespoke, specialist nature of the equipment meant that for each pilot, the value of this equipment ran into thousands of pounds.

The design process GWP undertook – including specialist software to calculate the precise amount of foam material for optimal protection – resulted in a solution which has proven successful in preventing damage to the Red Arrows’ valuable kit.

Contents

About the customer

The Royal Air Force Aerobatic Team (Red Arrows)

The Royal Air Force Aerobatic Team, commonly known as the Red Arrows, is one of the world’s premier aerobatic display teams.

Since 1965, the Red Arrows have been putting on displays, earning fame for their trademark “Diamond Nine” formation and precision flying. By the beginning of 2023, they had flown almost 5,000 displays in 57 countries.

Representing the speed, agility and precision of the Royal Air Force, the team is the public face of the service. They assist in recruiting to the Armed Forces, act as ambassadors for the United Kingdom at home and overseas and promote the best of British.

Based at RAF Waddington in Lincolnshire, the team comprises pilots, engineers and essential support staff with frontline operational experience. Together, they demonstrate the excellence and capabilities of the Royal Air Force and the service’s skilled and talented personnel.

The challenge

Protecting specialist equipment in transit

Each Red Arrows pilot is tailor-fitted with an aircrew protective helmet which provides communications, breathing apparatus and protection in the event of an emergency egress.

To protect them from gravitational forces while flying, pilots are also fitted with a set of full-coverage anti-G trousers to help combat the effects of G-force on the body.

Due to the specialist and bespoke nature of this equipment, each pilot’s kit can cost several thousand pounds. While a standard RAF Alpha Helmet can cost thousands, the customised version used by the Red Arrows would be significantly more due to its unique integration with the Hawk aircraft’s display technology and oxygen systems, potentially costing more than their display-running costs. The exact cost of a Red Arrows pilot’s helmet is not publicly available, however.

As the Red Arrows operate throughout the UK and globally, the support team required a solution for transporting the equipment carefully to ensure it remains fully protected.

The solution

Heavy-duty flight cases with bespoke foam

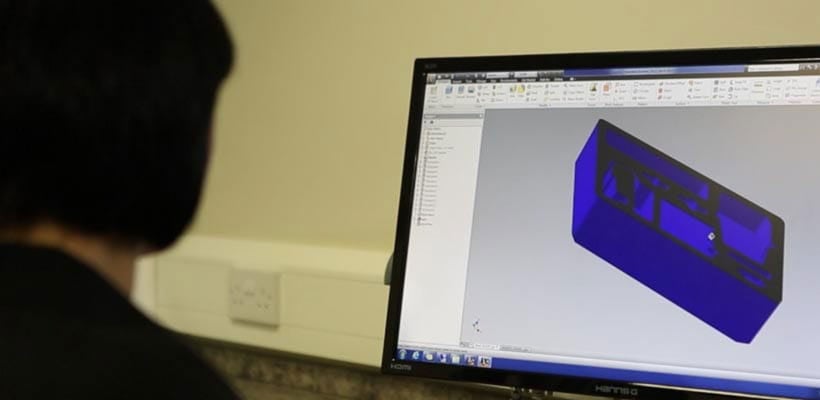

Following initial contact between GWP Protective and the Red Arrows, CAD designer Will Lamb conducted a series of design consultations with key stakeholders within the Red Arrows team.

Following this, Will accurately captured the dimensions and profiles of equipment that required protection, utilising the latest software and digitising equipment. GWP’s design team then imported the data into the CAD software used by GWP.

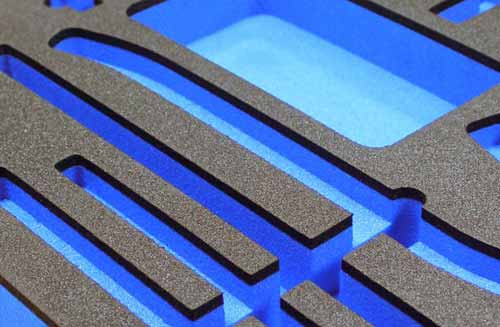

Having created draft designs for the foam inserts to protect the equipment, Will then used specialist software to calculate the precise amount of foam required for optimum cushioning protection, using multiple data points and theoretical impact testing.

Due to the size of the equipment and to ensure efficient transport, GWP determined that custom flight cases were most suitable for the outer container. The colours of the foam and cases were chosen to match the Red Arrows branding closely.

Following the production of an initial sample for appraisal, GWP manufactured the cases and foam at our production site in Salisbury, Wiltshire.

The results

Benefits for The Red Arrows

The main advantage that the cases offered the Red Arrows was the total prevention of damage to the vital, expensive equipment. The precisely calculated performance of the foam inserts prevents potentially thousands of pounds in repair bills and cancelled events, and displays.

Using the cushioning software, as well as ensuring that the equipment would not become damaged in the event of mishandling, also ensured that the size of the cases was kept to a minimum. As a result, transportation is more efficient and cost-effective for the support team.

The foam inserts also helped with organisation, with laser-engraved part numbers helping support crews return equipment to the correct section within the cases.

The outer cases also help prevent damage, offering resistance to moisture and dust ingress. Handles also make handling the cases easier.

Customer feedback

Comments from The Red Arrows

Sergeant William Runciman, IC Survival for the RAF Aerobatic Team, commented:

The cases look good and satisfy our key requirements – the most important of these being to protect the vital equipment that allows the team to put on such incredible displays.

Summary

Sourcing cases and foam for your business

By utilising a combination of advanced software, experienced designers, extensive knowledge of protective case performance, and in-house manufacture of both cases and foam, GWP Protective created a solution that provides genuinely tailored protection for the Red Arrows’ specialised equipment.

If you have specialist, fragile or expensive equipment that simply cannot suffer damage, please get in touch to see how we can help.

Share this article

Further reading

About the author

Will has exceptional knowledge of 3D CAD design and various materials, which he uses to engineer high-performance foam packaging.