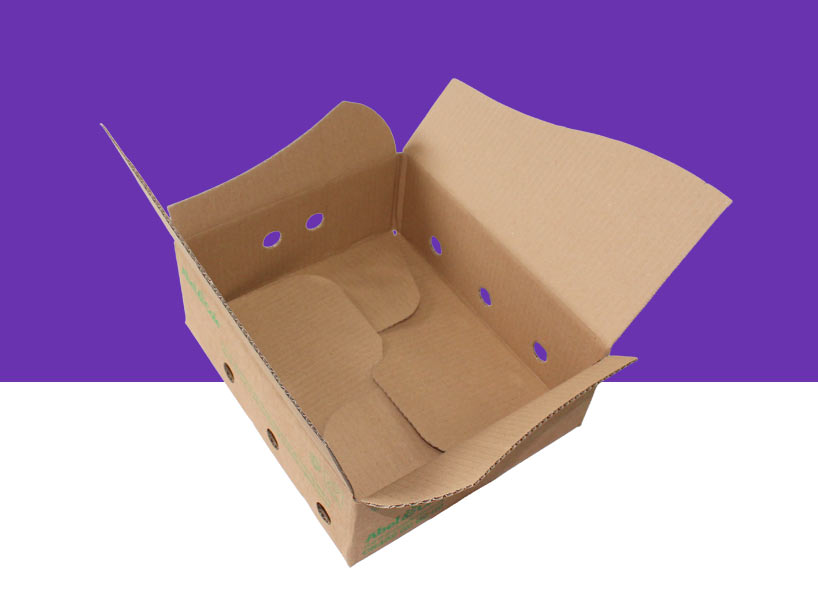

Fast assembly packaging

If you are looking for ways to improve the speed and efficiency of your packaging processes, crash lock boxes are a great option.

Supplied flat, crash lock boxes are easy to assemble in one quick action. The base simply folds out and locks together, allowing large numbers of boxes to be assembled quickly, consistently, and reliably without tape. Crash lock boxes offer one of the fastest and easiest options for manual packaging assembly.

At GWP, we have specialist manufacturing and printing equipment to produce custom crash lock boxes to your exact specifications. Bespoke sizes to minimise material use and transit costs. Printing to add banding and instructions. And carefully chosen material to tailor the strength and performance.

Benefits of crash lock boxes

Custom crash lock boxes, manufactured by GWP Packaging, offer:

What our customers say...

We’ve been working with GWP for around eight years. They supply all our packaging and we are absolutely delighted with them. Over time our needs have changed and they always respond swiftly with exceptional service. They know what we want and when we need it, and hold stock for us, and they never let us down. We feel they really understand our business, and they work very hard on the relationship.

Mark Barnett | Operations | The Consortium

A very friendly team who are able to supply narrow width multi-point glued cardboard shelf ready cases that I’ve been unable to source elsewhere. They have provided excellent technical support on complex design projects across a wide range of finishes and materials (not just cardboard…correx and foam too).

Saffy Allen | Google review

GWP are a responsive and pro-active company who manufacture all their own packaging products. They can also adapt each delivery exactly to match what we need, and when we need it. Their design team and prototyping ability are excellent and their innovative approach to design was a significant factor in us working with them. GWP have shown us that we can rely on them and as a result we have been able to significantly reduce the amount of packaging stock we have to hold.

Rebecca Crozier | Supplier Account Manager | Stannah

FAQs

What is a crash lock box?

Crash lock boxes – also known as self-locking cardboard boxes – are a type of packaging that requires minimal assembly. The base of the carton simply folds out and locks into place in a single action, meaning there is no need for glueing or taping.

How does a crash lock box work?

A crash lock base works by folding out as the person assembling the box pulls the corners of the box apart. As the sides of the base come together, the profile of their sides locks together, forming a solid base.

What materials are crash lock boxes made from?

Crash lock boxes can be manufactured from both single-wall and double-wall corrugated cardboard. Similar designs are available in Correx® plastic. However, GWP determines the best type of material to use based on your specific requirements, considering product size, weight and intended use. Doing this ensures you receive the most cost-effective option that doesn’t compromise performance.

Are crash lock boxes available in custom sizes?

All of the crash lock boxes that GWP manufactures are bespoke to your requirements. Not only does this allow for optimum performance, but it also minimises wasted material (and cost). It can also help reduce shipping costs, as you are not paying to ship empty space or excessive void fill.

Can you print crash lock boxes?

Crash lock boxes can have printing applied during the manufacturing process. Print can include everything from simple, single-colour logos to bright, striking graphics. It can also be helpful to include supplementary information such as handling instructions and recycling guidance.

Why GWP Packaging?

35+ years of experience

Designing and manufacturing corrugated and other forms of transit packaging has been the foundation of our business for over 35 years.

UK packaging experts

Our team of UK experts – everyone from designers to customer service to production – are on hand to share their extensive knowledge of packaging.

Competitive advantage

Our approach focuses on more than just creating the perfect packaging—we actively look to reduce your costs, improve efficiency, and support sustainability, too.

A business you can trust

As well as being a long-established, stable business ourselves, we are also part of Macfarlane Group PLC – the UK’s largest packaging distributor.

Disclaimer: Application images on this page may have been enhanced or created specifically to illustrate a products features and/or potential uses. Please see our content policy for further details.

Quotes, technical info and advice

Speak with our UK-based packaging experts

The information on this page has been collated, checked and approved by several of our corrugated packaging experts: