Benefits of composite packaging

Multi-material packs that can significantly benefit your business

If you are involved in shipping high-value industrial parts or products, you may be surprised by the advantages of using hybrid packaging.

Hybrid packaging is another name for composite packaging. It combines multiple materials to provide a bespoke level of protection for a specific product. Commonly used materials in hybrid packaging include wood, cardboard, foams and plastics (including bags).

This guide details several of the key benefits of using hybrid packaging (as well as a few drawbacks). It covers, amongst others:

- Environmental benefits.

- Costs and longevity.

- Usability, compatibility, and consistency.

Contents

Introduction

What is hybrid packaging?

If your company manufactures or transports specialist products, parts, or equipment, hybrid packaging can provide a range of benefits.

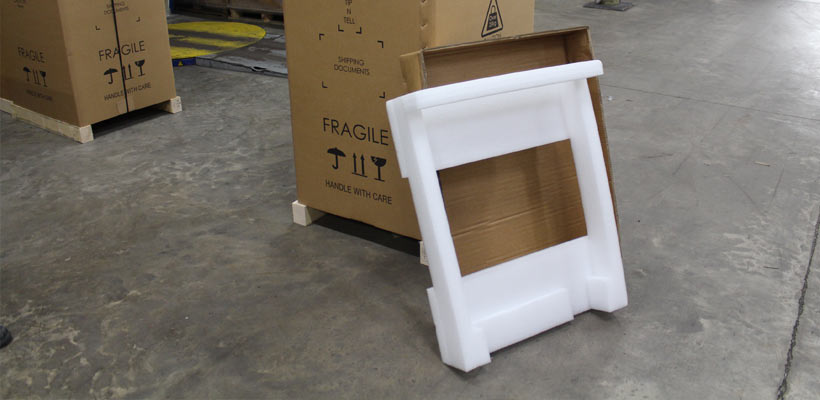

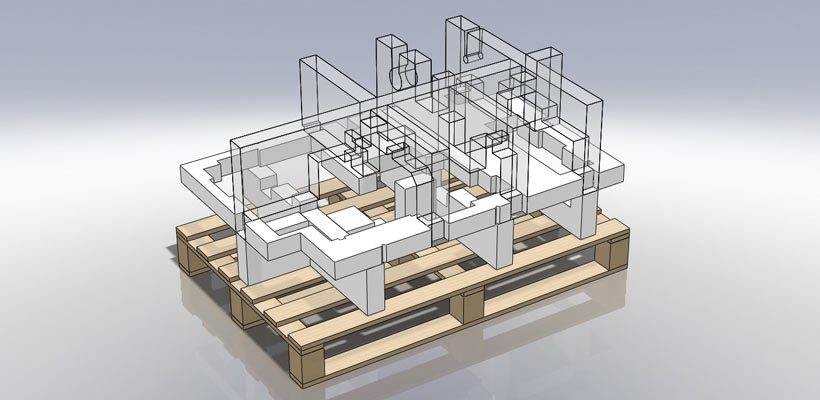

Hybrid packaging combines various materials, such as corrugated cardboard, timber, and low-density foams, to offer enhanced protection during transit. It’s ideal for industrial and high-value products or components, providing precise levels of protection for heavy, bulky, delicate, or expensive items.

Why is hybrid packaging required?

Businesses typically use hybrid packaging where specific performance or properties are required.

For example, companies can add Stratocell foam end caps to corrugated packaging to provide cushioning protection for the contents. Including a wooden pallet allows for improved handling of heavy items. A timber frame wrap, incorporating both cardboard and wood, can add structural strength and rigidity while retaining a lighter weight than an all-timber shipping case.

This level of customisation and versatility makes hybrid packaging so prevalent in specific market sectors.

Advantages of hybrid packaging

9 key benefits of using composite packaging solutions

So, what are the benefits of using composite or hybrid packaging? There are nine main advantages, ranging from the obvious to the often overlooked. Advantages of hybrid packaging include:

- Being fully customisable.

- Protection from mishandling.

- Protection from the elements.

- Reduces overall costs.

- Prevents project delays.

- Improves customer satisfaction.

- Enables easier handling.

- Reduces environmental impact.

- Offers potential reusability.

Fully customisable

Obviously, hybrid packaging uses various materials. The exact materials depend on your product, application, and requirements (and your packaging designers’ recommendations based on this).

As such, hybrid packaging is entirely customisable in terms of the materials used and, therefore, the properties provided.

However, in addition to choosing materials, inserts, and performance levels, hybrid packaging also allows for completely bespoke sizing, features (pallets, straps, inserts, ramps to load/unload products, etc.), printing, and more.

Protects from mishandling

Ultimately, hybrid packaging provides a tailored level of protection for your products, vastly reducing and (usually) completely eliminating transit damage.

The external material protects from knocks, scuffs, punctures, and similar physical damage. Inserts, particularly foam, prevent movement of your items within the outer package and also absorb shock, impact, and vibration. Specific foams can even provide a calculated level of protection for your items.

Protects from elements

Besides physical protection, composite packaging can also protect against adverse atmospheric conditions.

For example, water-resistant materials such as Correx or coated cardboard protect against splashes and moisture. VCI packaging can prevent corrosion of ferrous metal products, and features such as desiccant ports can help protect against condensation.

If you ship electronics or products that rely on them, it is also worth considering packaging that protects against electrostatic discharge (ESD).

Improves customer satisfaction

A lesser realised benefit of getting your products to your customers without damage is their satisfaction.

It is obvious that continually supplying damaged products to customers is likely to make them search for other suppliers and result in your company losing their business.

However, although the supply of undamaged goods is deemed a minimum requirement, the goodwill and satisfaction this reliability can provide can build up over the months and years. Being viewed as a reliable supplier can help you retain and win new business.

Prevents project delays

Similarly to customer satisfaction, having essential equipment arrive on-site damaged can have serious consequences.

For example, staff unable to do their jobs due to damaged equipment are unproductive at best and can result in severe project delays at worst. This also paints your business in a bad light, harming your reputation and longer-term success in winning business.

Easier handling

Features integral to your hybrid packaging can increase efficiency throughout your business and supply chain.

A simple example is having integral pallets on your packs (similar to pallet boxes), which allows for the easy movement of heavier items by forklifts.

More unusual but equally helpful features include hinged openings, lifting eyes and straps, and even ramps to help load and unload wheeled products.

Reduces costs

Although composite packaging is typically more costly initially, all of the other advantages detailed to this point lead to reduced ongoing costs for your business.

Preventing damage reduces costly returns and repairs. Improved customer satisfaction reduces the expense of retaining and winning new business. Preventing project delays avoids costly overruns (and delays in the following job or contract). Easier handling improves staff efficiency, reducing labour costs.

Effectively, hybrid packaging can have a significant, positive impact on your hidden and secondary costs.

Reduces CO2

A benefit of taking a custom approach to your packaging is the lessened impact on the environment.

Tailored packaging is typically more resource-efficient, only using the material required.

Similarly, optimised pack sizes reduce transit costs. You can ship more items in a single shipment, the weight is lower, and you do not pay to transport empty space.

Plus, with transit costs reduced through improved efficiency, you also see a reduction in the associated CO2 emissions.

Reusability

Finally, the robust nature of composite packaging means businesses can often reuse it.

Suppose you have a returnable loop set up as part of your supply chain (i.e., empty or partially loaded vehicles returning to your site after delivering to customers). In that case, you can easily retrieve and reuse your composite packs. This also reduces your ongoing costs and removes the requirement for your customers to dispose of the hybrid packaging you send to them.

Disadvantages

Recycling, weight, design complexity, upfront costs

However, there are a few disadvantages to composite packaging.

Most commonly, this includes the upfront costs, which can be higher than using single-material packs. While this is nearly always offset, it can make the business case for hybrid packaging more difficult in the short term.

The other main disadvantage of hybrid packaging is its recyclability. While most of the component parts (except foam) are easily recycled, the end user has to separate the materials to do so, which can be laborious and difficult.

Some businesses also cite the increased weight of hybrid packaging as a negative, adding to transport costs.

Finally, design complexity can often lead to longer lead times. Hybrid packaging requires an in-depth design process to ensure it offers the optimum performance, but this can require ongoing modifications and testing before a final solution is agreed upon.

Summary

Sourcing hybrid packaging

Despite these few disadvantages, hybrid packaging is nearly always an excellent option for protecting industrial and specialist products in transit, particularly where you cannot countenance any damage.

At GWP, we have more than 30 years of experience providing composite packaging to businesses of all sizes. We can also offer a full design service, manufacture your packaging at our UK manufacturing facility, and incorporate all of the required materials (nothing is outsourced, as is the case with many other suppliers).

Crucially, we can also advise – impartially – on whether composite packaging is the best option for your business or whether there are other alternatives that you should consider.

Please get in touch with us today for expert advice and assistance in finding the best hybrid packaging (or other) solution for your business.

Share this article

Further reading

About the author

Stuart boasts over 20 years of top-level experience as a packaging design engineer, in roles at Insit Moulded Packaging (IMP) and Macfarlane.

Products in this guide

Get in touch

Related guides

6 essential pallet optimisation tips to maximise efficiency

UK pallet sizes – what are they, and do they affect your packaging?

7 advantages of using wooden export crates (and 5 disadvantages)

What is ISPM 15? A comprehensive guide

Export packaging guide – 7 considerations for international shipping

Shipping cases: 5 options for safe transit of your goods