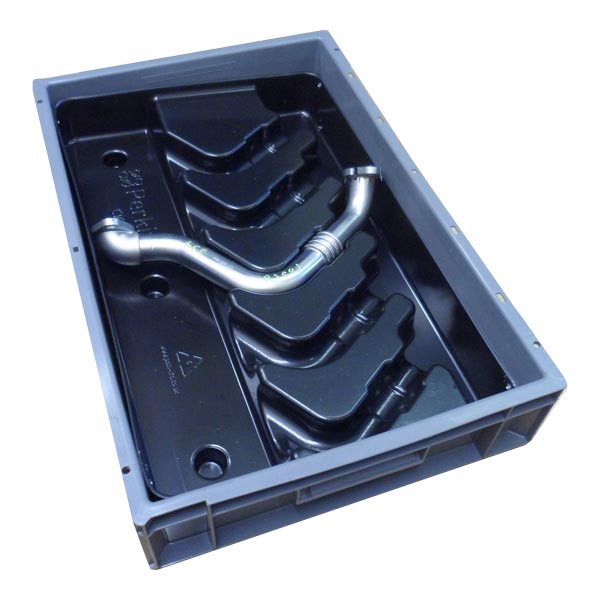

Vacuum formed packaging trays

If you need a versatile handling solution – suitable for standalone use or as a tote box insert – you should strongly consider vacuum formed trays.

Vacuum formed trays are custom-shaped plastic containers. They are manufactured by heating a thermoplastic sheet and using a vacuum to shape it over the contours of a mould. This process creates a rigid, durable tray with recesses tailored precisely to specific components, offering excellent protection. Vac form trays are ideal for food, automotive, medical and other manufacturing applications.

At GWP Correx®, alongside vacuum formed packaging, we can offer Correx® trays and foam dunnage. As such, our experts can provide impartial advice on the most suitable and cost-effective option for your specific requirements.

Please note: Correx® is a registered and/or unregistered trademark of Corplex Plastics UK Ltd, its parent, subsidiaries and/or affiliates.

Benefits of vacuum formed trays

By using vac trays and inserts at your business, you benefit from:

What our customers say...

Always happy to help with great customer service. Couldn’t ask for any more.

Shane Munton | Damasco (Google review)

GWP are friendly and easy to deal with, great customer service and give quick responses/answers on via both email and over the phone. Products are good quality, quick lead times and we like that they are able to provide samples before the customer proceeds with an order.

Parris James | Buyer | Vodex Ltd

GWP provide an excellent service. Always prompt and friendly, their products are of good quality and their staff are always quick and efficient in resolving any problems that may arise. Highly recommended!

Mark Elmes | Purchasing | Kaisertech (Google review)

Colours and options

Available colours and printing

Blue

Black

Grey

Additional colours are available by request, subject to minimum order quantities (MOQs).

Additional considerations

Sheet Thickness: Generally ranges from 0.25mm to 6mm, with thinner sheets (0.010 – 0.080 inches) used for detailed, lower-strength items, and thicker sheets for durability.

Mould Shrinkage: High-density polyethylene (HDPE) has a high shrinkage rate (2.0 – 3.5%), while ABS and HIPS have lower, more stable rates (0.4 – 0.7%).

Material options

Acrylonitrile Butadiene Styrene (ABS): High impact resistance, rigidity, and strength. Suitable for automotive parts, casings, and durable consumer goods.

Polyvinyl Chloride (PVC): Durable, chemical-resistant, and fire-retardant. Suitable for industrial, medical, and packaging applications.

High-Impact Polystyrene (HIPs): Low-cost, lightweight, and easy-to-form. Suitable for prototyping, product packaging, and trays.

Polyethylene Terephthalate Glycol (PETG): Excellent clarity, high impact resistance, and food-safe. Suitable for medical packaging and displays.

Polypropylene (PP): Lightweight with high chemical resistance and flexibility. Suitable for food containers.

FAQs

What is the difference between vacuum forming and thermoforming?

Vacuum forming and thermoforming are essentially the same processes: heating plastic to a malleable temperature before forming it into a specific shape. The difference in vac-forming, however, is the additional process of using a vacuum to force the plastic material to conform to the mould.

What plastic is used for vacuum forming?

Manufacturers can use several different plastics for vacuum forming. Suitable materials include vacuum-forming grades of ABS, PETG sheets, and HIPs (High-Impact Polystyrene sheets). HIPs are the most commonly used material for the manufacture of vacuum-formed trays.

Are vacuum formed trays recyclable?

You can recycle HIPs and other Polystyrene materials used in manufacturing vacuum tray packaging, minimising environmental impact. Additionally, High Impact Polystyrene is cost-effective to produce, making its use widespread in the food industry.

Are vacuum forming tools expensive?

The tooling cost for vacuum-formed trays is significantly higher than for Correx® or plastic divisions. However, compared to similar tooling such as that used for injection moulding, vac-formed tools are relatively low-cost. The low unit costs of the finished trays also make them competitive when produced in mid- to high-volume.

What is material shedding?

If you use other types of tote inserts, such as cardboard or foam, shedding of material can occur over prolonged, repeated use. Shedding occurs when tiny particles of the foam material rub off, creating dust and fine debris that can contaminate or damage parts (known as FOD – foreign object damage).

Why GWP Correx®?

20+ years of experience

A team of UK experts. In-house manufacture. Short lead times. Over 20 years of experience in manufacturing industrial plastic trays. Benefit from all this and more by working with us.

UK Correx® experts

Everyone at our business – from our designers through to our customer service team, production operatives to technical sales reps – has extensive knowledge of Correx® material.

Competitive advantage

We won’t just sell you a product. Working closely with key stakeholders at your organisation, we’ll develop a solution that delivers genuine long-term commercial advantages for your business.

A business you can trust

Although continuing to operate as an independent business, GWP Correx® is proud to now be a part of Macfarlane Group PLC – the UK’s largest packaging distributor.

Disclaimer: Application images on this page may have been enhanced or created specifically to illustrate a products features and/or potential uses. Please see our content policy for further details.

Quotes, technical info and advice

Speak with our UK-based Correx® experts

The information on this page has been collated, checked and approved by several of our Correx® packaging experts: