ESD plastic containers

If you need a bespoke handling solution for your static-sensitive parts or products, Corriplast conductive tote boxes are your best option.

Corriplast conductive tote boxes are a type of conductive plastic container. The unique handle design allows you to source bespoke sizes, maximising space and transport efficiency (by eliminating empty space inside the container). The ESD (electrostatic discharge) performance and durability of the conductive Correx material protects contents from static and physical damage.

At GWP Conductive, we are the UK’s largest manufacturer of anti-static packaging (with 80% market share). We offer stock products via a Europe-wide distribution network and bespoke design provided by our experienced team.

Sizes and technical information

Key features

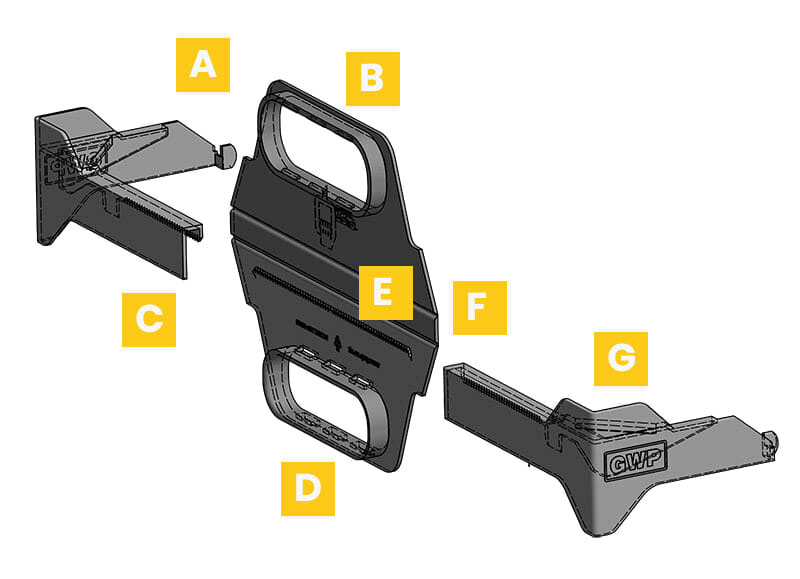

A

Packaging location clip

B

Snap fit handle locking feature

C

Interlocking teeth on the rear side of end components lock into those on handle, allowing tote to be created to any size

D

Rear handle fits inside front handle for enhanced aesthetics and comfortable grip

E

Interlocking teeth on inside of the handle component lock into teeth on end / corner sections when folded over, eliminating the need for screws

G

Stacking platform and movement guards on each corner

F

Living hinges allow handle to fold over

Assembly

Firstly, the die cut Corriplast® material is folded as if assembling the tote / container

The side components are adjusted to the required packaging width and are then located on the tote corners.

The handle is placed on top of both the side components and is then folded over them.

The teeth from both the handle and side components interlock when folded and secure the three components together, preventing them coming apart.

The final step of the assembly process ends with the front and rear handle being pushed together. The cantilever snap features built into the hand holes locate, fixing the handle securely.

Benefits of Corriplast tote boxes

By using Corriplast conductive tote boxes at your business, you can expect several benefits:

FAQs

What are Corriplast totes made from?

Corriplast is a conductive version of Correx® – a corrugated plastic material. The main benefit of Correx® – and therefore Corriplast – is that it can be fabricated to create custom-sized conductive totes, containers, and packaging that offer strength and performance approaching that of moulded plastic options (but are only available in stock sizes).

Is it more expensive to use custom-sized conductive plastic containers?

If you are transporting a high volume of products (and therefore totes), custom sizes can reduce your transit costs. Whilst you have an initial tooling cost to absorb, by eliminating the shipping of empty space within the totes, you can ship more in one load, reducing the number of journeys and overall costs.

Do Corriplast ESD tote boxes protect items during handling and transit?

Custom-sized containers, such as the Corriplast Tote Boxes, minimise the movement of parts within the container, which, in turn, can help prevent damage caused by shock, impact, or mishandling. The Corriplast material is also durable and hardwearing, and protects against dust and moisture.

What are the benefits of Corriplast compared to moulded plastic ESD totes?

When selecting a stock-sized moulded container, you must always choose a size that is slightly too large to accommodate your products or components. The extra (or wasted) space is then typically left empty or filled with void fill. This wasted space, however, means you can store fewer items in your warehouse. Takes more trips to move when being handled by production staff. And even means you can ship fewer items in a single consignment. All of this leads to increased costs and decreased efficiency and productivity.

Is it worth adding dividers to these conductive tote boxes?

Adding dividers, such as those made from Corstat®, Corriplast, or anti-static foam, can offer significant benefits for your business. They make packing and unpacking easier, speed up visual stock checks, help prevent damage by preventing parts from moving during transit, and even help avoid overloading the container. This final point can lead to product damage or even poor health and safety.

Why GWP Conductive?

35+ years of experience

GWP Conductive has been successfully designing and manufacturing Corriplast and other ESD packaging and handling products for over 35 years.

UK ESD packaging specialists

Our UK-based team of ESD specialist designers and experts are available to help with any conductive packaging requirements your business may have.

Market leaders

With an 80% plus share of the UK ESD packaging market, you can be sure that all GWP Conductive products deliver the highest levels of performance.

A business you can trust

GWP Group – whilst remaining an independent business – is now part of Macfarlane Group PLC, the UK’s largest protective packaging distributor.

Disclaimer: Application images on this page may have been enhanced or created specifically to illustrate a products features and/or potential uses. Please see our content policy for further details.

Quotes, technical info and advice

Speak with our conductive packaging experts

The information on this page has been collated, checked and approved by several of our conductive packaging experts: