Plastic reel alternative

If your business manufactures any wound products, such as cables, hoses, rope, or filament, cardboard spools are a lightweight and environmentally friendly alternative to plastic reels.

The light weight of corrugated cardboard spools allows for easy handling and helps reduce transport costs and emissions. Available in semi-bespoke sizes, cardboard spools and reels are also available with custom print and are easy to recycle.

At GWP, we custom-engineer your spools to meet the specific strength and durability requirements of your application. Our fully automated manufacturing process, using purpose-built machines at our UK production site, guarantees exceptional accuracy and quality.

Benefits of corrugated cardboard spools

By using or switching to corrugated cardboard spools, you can expect:

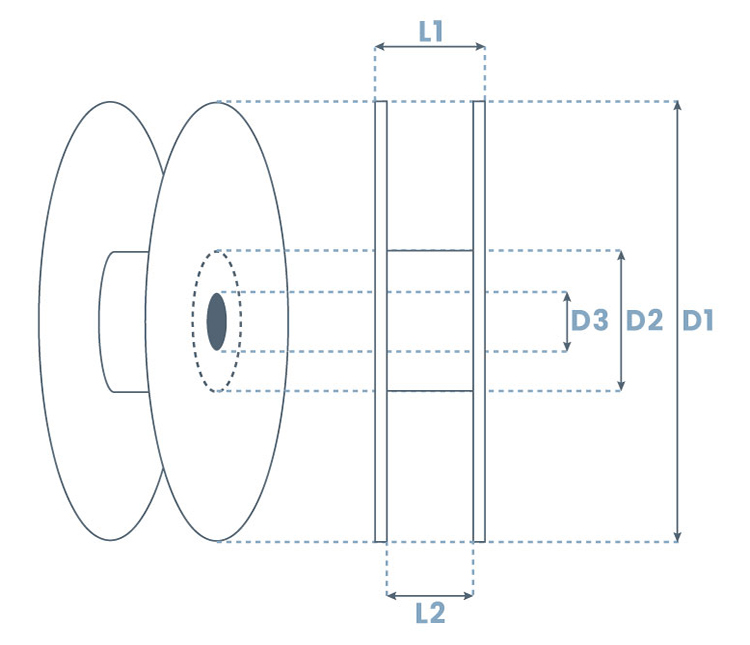

Spool measurements guide

| Measurement | Reference | Notes |

|---|---|---|

| D1 | Flange | Min: 40mm from core - Max 600mm diameter |

| D2 | Core | 150mm - 191mm |

| D3 | Centre Hole | NA |

| L1 | Width | NA |

| L2 | Traverse | Min 25mm - Max 400mm |

FAQs

What size spools are available?

Cardboard spools are available in semi-bespoke sizes to suit your application (although there are some limitations with very small or very large reels). This dimensional flexibility means that your spool can be the perfect size for your winding equipment, transport and/or product.

Are cardboard spools cheaper than plastic or plywood spools?

Depending on the size, configuration and volume of spools required, using cardboard reels is typically more cost-effective than plywood or plastic options. There are also other related cost savings, including custom sizes and lower weight, which result in reduced transit costs.

Are cardboard spools lighter than their alternatives?

Corrugated cardboard spools are lighter in weight than both moulded plastic and plywood options. This weight saving can not only improve safety and ease of handling for your employees and spool users but can also directly impact your shipping costs.

Are cardboard spools environmentally friendly?

Cardboard spools are the most environmentally friendly option currently available on the market today. They are typically manufactured from 80% recycled materials and are fully recyclable at the end of their lifespan. They are also biodegradable should they end up in landfill.

Are cardboard spools suitable for 3D printer filament?

The use of cardboard spools is becoming more widespread for use in holding 3D printer filament (as the adoption of this technology becomes more established). They are also suitable for storing and transporting cables, tubing, rope, string, chains, flexible extrusions and even pressed electronic components.

Bespoke

Our designers create packaging tailored to your exact requirements for optimum performance and cost.

Cost-effective

We also have a range of proven strategies to drive down costs across your business’ operations.

Sustainable

We use recycled, recylable and FSC-certified material alongside sustainable and commercially effective designs.

Quotes, technical info and advice

Speak with our UK-based packaging experts

The information on this page has been collated, checked and approved by several of our corrugated packaging experts: