Foam packaging manufacture

Conversion of foam into protective packaging

If your business uses protective packaging, you may have already taken advantage of foam conversion.

Foam conversion is the process of turning foam material into usable products. Processes include die cutting, CNC routing, waterjet cutting, sawing, and laminating. Items created by foam conversion include protective case inserts, foam packaging such as end caps, and consumer products, including insoles, roll mats, and acoustic foam. Materials, including Plastazote and Stratocell, are commonly used by foam converters.

But what is the foam conversion process? How does it work? And how can you use this knowledge to select a foam converter for any upcoming projects or requirements?

To answer these questions, this guide covers the following:

- The typical materials used in foam conversion.

- Foam conversion methods and processes.

- The types of products manufactured from foam.

Contents

Introduction

What are foams used for?

It can be surprising how commonplace foams are in everyday life. They are found in cars and vehicles to reduce cabin noise. Various materials are used in specialist aerospace applications. They are popular for various audio equipment (most notably microphones) and commonplace in insulating buildings. They are even used for sports equipment, such as shoe insoles and roll mats.

But the most common use for foam—and the one you are most likely to see on a regular basis—is protective packaging. From end caps on consumer electronics to high-performance case inserts for protecting tools, foam packaging can provide excellent protection for a wide range of items during transit.

Foam manufacturer vs converter

However, it is essential at this stage to distinguish between foam manufacturers and foam converters.

Foam manufacturers, as the name suggests, produce the raw material that foam converters use. Typically using plastics (although a range of wood and plant-based foams are now becoming available), foam producers use a range of techniques to manufacture materials with different densities, properties, colours, thicknesses, and intended applications.

Large manufacturers of foam include Sealed Air and Zotefoams.

Foam converters take these materials and use various equipment and processes to convert them into usable products.

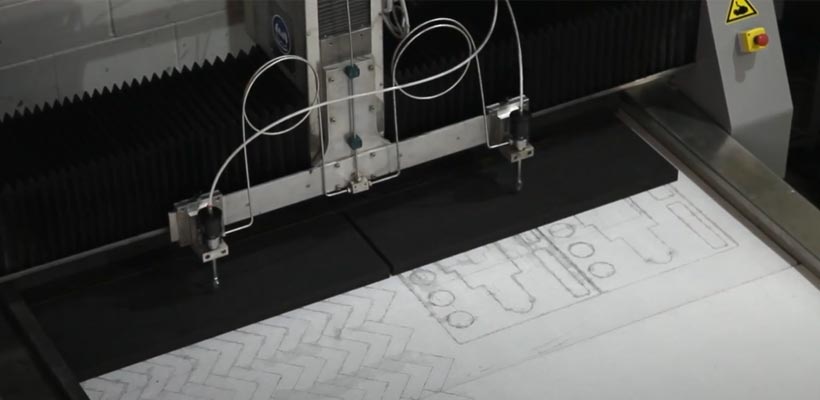

For foam packaging and inserts, the process typically involves a specialist designer analysing the products that require protection before creating a bespoke design that considers multiple factors. Key considerations include product size, fragility, outer packaging, expected handling conditions, and more.

Converters transfer these designs directly from the CAD (computer-aided design) systems to the conversion equipment.

Foam conversion materials

Materials used in foam conversion

Several materials are used in foam conversion, each with different properties, attributes and end uses. Different foam conversion processes are often suited to specific material types, meaning it is vital that specialist foam engineers and designers select an appropriate method for specific packaging applications.

The main types of foam converted into packaging are:

- Plastazote.

- Chemical block.

- Stratocell.

- Ethafoam.

- Wood foam.

Foam conversion processes

Ways in which foam packaging manufacture takes place

There are a variety of foam conversion techniques that converters use to create foam products, such as packaging and case inserts.

The main foam conversion processes are:

- Die cutting.

- CNC routing.

- Waterjet cutting.

- Sawing.

- Splitting/laminating.

- Laser cutting and engraving.

Foam die-cutting

Die-cutting foam conversion process

In essence, die cutting is the process of using a cutting tool (die) to press foam to specific shapes, creating bespoke cushion packaging and case inserts. The process is also popular for non-packaging products such as upholstery foam.

Although this process can cut through only specific depths of foam (a process known as kiss-cutting), it is more common for the die to cut through the entire depth of the material.

Die cutting is carried out on a flatbed press as part of the foam conversion process. However, the requirement for tooling generally means that it is used for larger runs, where the cost of this tooling is more easily absorbed.

Applications for die-cut foam

The advantages of die-cutting foam are its speed, consistency, and repeatability. It is ideal for higher-volume runs and particularly suited to low-density materials such as Stratocell and Ethafoam.

The main downside with die cutting is that as pressure is applied to the material, it begins to compress. Due to this, the resulting cut is not perfectly straight, with a slight concave curve to the edges. This does not affect the cut foam’s performance, however, and is merely aesthetic.

This foam conversion process is commonly used to manufacture foam end caps, foam-lined boxes, and other forms of higher-volume foam packaging.

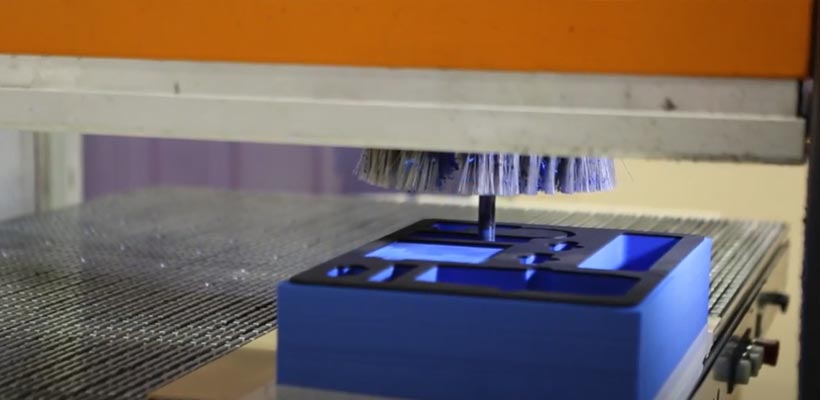

CNC routed foam

Computer numerical control process

CNC routing is the main foam conversion process used for creating intricate, 3D shapes within a higher-density material, such as Plastazote.

CNC stands for “computer numerical control,” which is effectively a computer-controlled process linked directly to foam designers’ CAD software.

By uploading the 3-dimensional profiles to the machine, the router head can systematically cut away foam material to create exceptionally intricate shapes to very tight tolerances.

The process also ensures that the match between the item and the case insert is as close as possible by first digitising the product to be placed within the routed foam insert.

Applications for CNC-routed foam

CNC routing produces consistent, high-quality engineered foam products. Also, because physical tooling costs are eliminated (unlike die-cutting), the process can create one-off routed foam inserts very cost-effectively.

As the recesses created within the material are so precise, the resulting inserts prevent tools or equipment from moving when placed in them, significantly reducing the potential for damage. Additional software can also calculate the precise amount of material required to absorb shocks, impacts, and other forces.

The only real disadvantage of CNC routing is its speed – the process is considerably slower than die cutting, for example.

Due to this, CNC routing is commonplace when creating case inserts, shadow boards, tool control foam, and even gift box inserts.

Waterjet cutting

Abrasion cutting process

Waterjet cutting sits somewhere between CNC routing and die cutting.

Waterjet cutting equipment effectively uses a CNC-controlled jet of water at high pressure to cut intricate shapes in foam materials.

Water jet cutting has several advantages over traditional die-cut foam and routed foam inserts. For example, it leaves no radius in corners, is exceptionally precise, and does not cause heat build-up, which can affect the foam’s properties.

Besides this, it can also create narrow slots to much greater depths than other methods and provide a very clean, smooth finish with no dust residues. It can also boast accuracy of up to 0.005″ (0.13 mm) and repeatability of 0.001″ (0.025 mm).

Foam fabricated in this manner produces no hazardous waste, eliminates airborne dust particles and fumes, and uses very little water due to its “closed loop” setup.

Applications for foam waterjet cutting

Unlike CNC routing, waterjet cutting cannot cut to specific depths—it simply cuts all the way through the material (as die cutting does). It is also slower than die cutting, and the water used can mean some drying time is required after items are manufactured.

However, its precision means that waterjet-cut foam can be layered and stuck together to create high-performance protective case inserts. It is also popular for creating foam dunnage, which is used within tote boxes to protect automotive, aerospace, and other industrial parts and products as they move through supply chains.

Sawing/cutting

Cutting foam to size

As the name would suggest, sawing foam involves cutting it to size. This can be as simple as cutting overside foam sheets to a size suitable for another foam conversion process or trimming down foam that has already undergone conversion.

Converters usually cut foam with a bandsaw or a hot wire cutter, which effectively melts the material as it passes through it. However, certain computer-controlled saws offer an alternative to die cutting (and avoid the issue of concave edge profiles).

Applications for cut foam

Foam sawing is used across virtually all other conversion processes. As mentioned, it can trim sheets and raw material to a size suitable for other conversion equipment and size foam that has been laminated (e.g., glued together) to create neater edges.

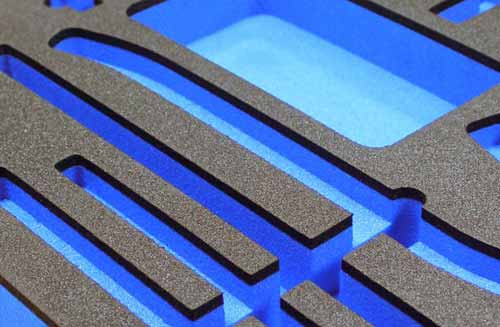

Splitting and laminating foam

Glueing and heat welding foams

Most foam suppliers only offer a range of standard thicknesses (determined mainly by the extrusion and manufacturing processes). These sizes mean it is often necessary to split down larger sheets and/or laminate multiple foam sheets together to create the desired material thickness.

Foam is typically laminated using either glue or heat welding. Both methods provide a robust and permanent bond.

Laminated foam applications

Most foam conversion requires material to be laminated at some point in order to create the desired thickness of the material.

However, a significant benefit of laminating foam, particularly Plastazote, is that it allows converters to use different colours together. This mixing of materials allows for some striking visual effects, such as a black top layer and a bright colour showing through once cut. The finished effect makes laminating foam ideal for creating high-quality foams for sample cases and even retail packaging.

Besides the improved aesthetics, laminated foam is also ideal for creating shadow boards or tool control foam, which immediately highlights if a tool or part is missing.

Laser etching and engraving

Adding logos, part numbers and instructions

Many people refer to “laser cut foam“, but this conversion method is not commonplace amongst most commercial foam converters.

Instead, lasers are often used to create markings on the surface of the foam. The process uses the laser—a high-energy source of radiation—to generate heat on the foam’s surface and cause a reaction. The result is either a darkened surface colour or the removal of the top layer of foam.

Laser-etched foam applications

Foam laser engraving has several obvious benefits.

Firstly, it allows you to add your branding and logos to the foam’s surfaces, making it ideal for presentation packaging and applications such as sample cases.

Secondly, this foam conversion process can directly add part numbers and handling/safety instructions onto the foam. Doing so can aid the productivity and efficiency of service engineers and field technicians who take tools out on-site in carry cases.

Summary

Choosing a suitable foam conversion process

Unless you have strong technical knowledge of foam (and the specific material grades, complementary packaging, intended application and various other factors), it can seem impossible to know which foam conversion process is the most suitable.

However, at GWP Protective, our team of experts—from designers to product advisers to production staff—has extensive knowledge in all aspects of foam conversion. In fact, we have been among the UK’s leading foam converters for over 25 years.

Primarily utilising Plastazote® (for high protection applications), Stratocell and Ethafoam (for single trip requirements) plus a range of other specialist foams, we can fabricate your foam inserts and packaging using a wide range of techniques. Many utilise cutting-edge processes and CAD CAM technologies at our Salisbury production facility.

So, if you need any form of foam conversion, engineered inserts, or protective packaging, please contact us.

Share this article

Further reading

About the author

Initially joining GWP Protective back in 2004, Richard’s vast, specialist knowledge and experience mean he now heads up the business as General Manager.

Products in this guide

Get in touch

Related guides

Plastazote® foam – what is it and should you be using it?

The 6 tell-tale signs you need protective foam inserts

Sustainable foam packaging options available to your business

Eco-friendly foam packaging – is now the time to switch?

Enhancing your protective cases with foam inserts

Analysis: Is foam packaging bad for the environment?

Polystyrene alternatives: should you be using them?

How to guide: Using cubed foam inserts for cases

Wood foam packaging – what is it, and should you be using it?