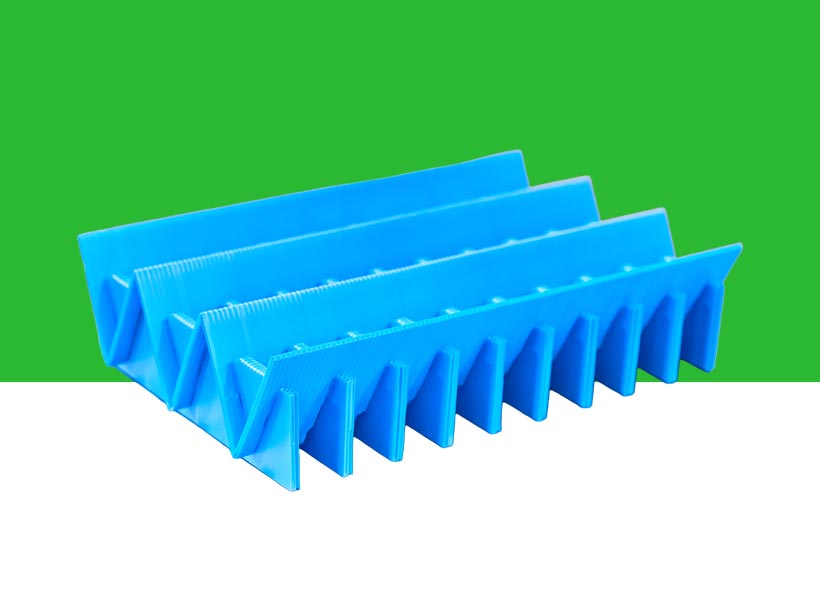

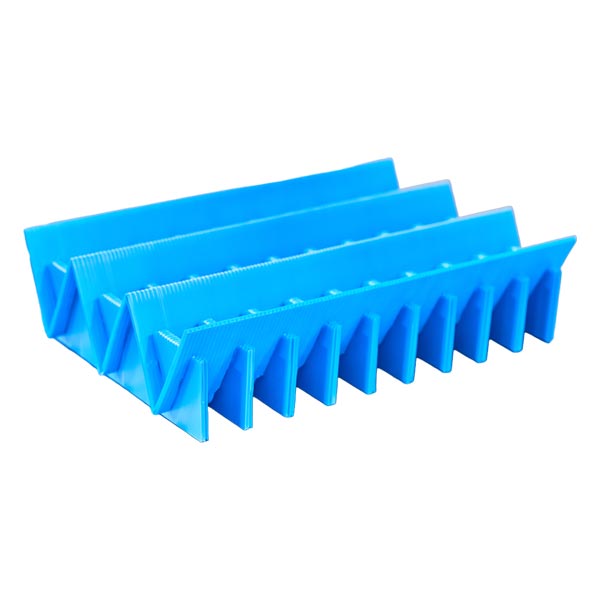

Corrugated plastic dunnage

If standard Correx® dividers or other forms of corrugated plastic dunnage are not suitable for your application, custom plastic inserts can provide the performance and properties you need.

Custom plastic inserts are bespoke dividers and inserts used in returnable packaging. Often using die-cut Correx® material to match the shape and size of specific parts or components, bespoke inserts can provide a more precise level of protection.

At GWP Correx®, we have been manufacturing bespoke corrugated plastic dunnage for over 25 years. Our in-house designers and extensive production equipment allow us to manufacture your custom tote inserts to almost any specification using a combination of Correx®, Bubble board, foam, and even vacuum-formed trays.

Please note: Correx® is a registered and/or unregistered trademark of Corplex Plastics UK Ltd, its parent, subsidiaries and/or affiliates.

Benefits of custom plastic inserts

Using custom plastic inserts can provide you with several benefits, including:

What our customers say...

GWP really helped us out. They quickly came up with a simple but very effective Correx solution. We’re very pleased with the outcome and we had quite a fun and successful team building hour putting them all together!

Paul Wilson | Project Manager | Heathrow Terminal 2

We previously used cardboard but needed something more robust and with better performance around water. Lead time and price were both excellent. The team and service was quick, reliable, helpful and friendly.

Danielle Roach | Latis Scientific

We have stayed with GWP because the service is so good. The team is friendly, hold the items needed in stock and the pricing is competitive. We buy thousands of boxes each year, plus foam and division sets.

John Wayman | Managing Director | Bondline

Colours and options

Available colours and printing

Blue

Blue

Green

Red

Yellow

Black

Grey

White

Additional colours are available by request, subject to minimum order quantities (MOQs). Single colour to full colour (CMYK) printing is also available. Please enquire for further details.

Material options

Standard Correx, suitable for packaging applications, is available in 3mm (450gsm), 4mm (700gsm) and 5mm (1050gsm) grades.

Our technical support and design teams can advise on a suitable grade for your specific application.

FAQs

What benefits do custom plastic inserts have over standard ones?

Custom plastic inserts can provide several benefits over stock divider sets, layer pads and foam dunnage. Advantages include being perfectly tailored to your specific application, typically resulting in efficiency and productivity gains. Custom inserts can also significantly reduce damage caused through mishandling, further lowering your ongoing costs.

What are custom inserts manufactured from?

Whilst using Correx® material is common for custom plastic inserts, they frequently combine many different materials. These can include fabric-laminated Bubbleboard and foam inserts or blocks. Combining materials can help tailor performance levels to provide the optimum protection.

Are custom inserts suitable for my existing handling containers?

It is possible to develop corrugated plastic dunnage that can be used inside your existing handling containers (such as Correx® totes or Euro containers). Doing so can reduce your upfront costs while extending the life of your existing returnable packaging.

How long does custom corrugated plastic dunnage last?

One of the key benefits of corrugated plastic dunnage is its longevity. Even with repeated loading and unloading, custom plastic inserts manufactured from Correx® can last upwards of 50 uses and often well over 100. Being easy to clean also helps increase their longevity.

What is a kitting tray?

A kitting tray is traditionally a small, often vacuum-formed tray that stores the different parts needed for a specific assembly operation. However, larger-scale versions of these – effectively tote containers with dividers to house all components required by a production operative – are also growing in popularity.

Why GWP Correx®?

20+ years of experience

Having designed container inserts, dividers and fittings for over 20 years, we are now the UK’s largest independent converter (by volume of material).

UK Correx® experts

We have a dedicated team of experts who focus solely on Correx, each with specific, detailed knowledge of the material and its applications.

Competitive advantage

Whether you need to reduce costs, enhance your efficiency, minimise transport, improve sustainability, or something else – we can help.

A business you can trust

Although continuing to operate as an independent business, GWP Correx® is now part of Macfarlane Group PLC – the UK’s largest packaging distributor.

Disclaimer: Application images on this page may have been enhanced or created specifically to illustrate a products features and/or potential uses. Please see our content policy for further details.

Quotes, technical info and advice

Speak with our UK-based Correx® experts

The information on this page has been collated, checked and approved by several of our Correx® packaging experts: