Prevent the loss of tools

Tips and advice to prevent foreign object damage

If you or your team service or repair commercial machinery, industrial equipment or even aerospace engines and systems, preventing foreign object damage is essential.

Foreign Object Damage (FOD) is damage that is caused by foreign objects entering machinery or systems, notably in aviation. These objects, such as debris or tools, can cause equipment failure or structural damage. Preventative measures include regular inspections, FOD detection systems, and cleanliness protocols that reduce risk.

However, one of the most essential strategies to prevent foreign-object damage is robust tool-control processes.

As such, in this guide, we’ll discuss the key regulations governing tool control, explore the benefits of effective tool control, and present a practical solution for implementing an efficient tool control system.

Contents

Introduction

Foreign object damage in the aviation and similar industries

Modern aviation is one of the safest and most secure means of transportation, in part due to rigorous safety and security checks.

But what most people don’t know is the extraordinary efforts airlines are making. There are, in fact, many measures and guidelines in place to ensure that planes are as safe as possible.

Why is foreign object damage such a problem?

As recently as 2015, an Airbus helicopter crashed in Australia after an engineer left a tool behind during maintenance.

Similarly, a screwdriver caused significant damage to an aeroplane propeller, which led to additional damage to the fuselage during an incident in 2018.

So, whilst leaving a tool in or near an aircraft or its engine is an inconvenience, it is also a potentially catastrophic safety risk. As a result, proper tool control is essential to eliminating aircraft accidents and incidents.

Tool quality control issues also cost the aviation industry more than £500 million annually.

Tool control is also vital for preventing costly damage in various other applications, including the servicing and maintenance of industrial equipment and machinery.

Tool control

What is it, and why is it important?

One of the critical measures implemented by airlines and enforced by regulatory bodies is ensuring that engineers or service technicians do not leave foreign object debris in any part of the engine or aircraft systems after routine maintenance.

If a toolbox contains a random jumble of wrenches, screwdrivers and other tools, how can you tell if something is missing?

As such, organisations such as airlines must be able to inspect and monitor the tools and equipment used to maintain their aircraft.

Ensuring that all aviation mechanics comply with these regulations can be time-consuming for both mechanics and airlines. It is, however, a critical process and is the primary goal of most tool control policies.

Tool control essentially involves assigning a designated storage location for each tool when not in use. Doing this enables swift identification in the event of loss or misplacement of tools or equipment, thus preventing tools from causing potentially catastrophic damage.

Aviation regulations

What are the CAA and FAA tool control regulations?

Most UK airlines have a tool control and accountability policy, as outlined by the Civil Aviation Authority (CAA). Specifically, Policy 145-2 Equipment, Tools and Materials – OTAR Part 145.109. The Federal Aviation Administrator (FAA) policy in the United States is CA number 150/5380-5B.

The policies are naturally very similar, but in the UK, the CAA states:

Tools and equipment

“(a) All tools and equipment which need to be checked for maintenance or calibration because they are necessary for measuring specified dimensions and tightening torques, etc., must be identified and listed in a control register, including all personal tools and equipment that the organisation agrees to use.”

Tool control

“(b) Control of these tools and equipment requires that the organisation have an inspection/maintenance procedure, and, where applicable, regularly calibrate these items and communicate to users that the item is on schedule for inspection, service, or calibration.”

Tool labelling

“(c) A clear system of labelling all tools, equipment and test equipment is therefore necessary to give information on when the next inspection, service, or calibration is due and whether the item is unusable for any other reason where it may not be obvious. A record must be maintained for all precision tools and equipment, as well as a record of calibrations and standards used.”

“(d) Inspection, maintenance, or calibration shall regularly follow the equipment manufacturer’s instructions, except where the organisation can demonstrate through historical calibration and/or maintenance results that a different period is appropriate in a particular case.”

Implementing tool control

Using shadow board foam to prevent costly damage

Tool control is essential to ensure that engineers and service technicians can account for all tools upon completing their tasks. Your staff can only achieve this if every tool has a designated place for storage when not in use.

The CAA regulation also states that tools must be identifiable, listed, labelled, and available for regular inspection.

One of the most effective ways to achieve this is with tool control foam.

What is tool control foam?

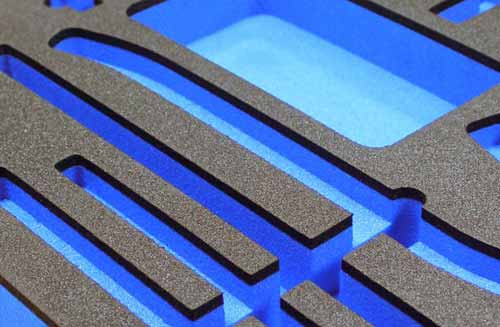

Tool control foam, or shadow boards, is a two-tone foam insert for a toolbox or protective case.

Usually, tool control foam has a black or dark-coloured top layer, with a bright, contrasting foam colour for the pockets or recesses used to keep tools.

This colour difference can quickly help engineers and technicians see if a tool is missing from its designated location. Effectively, it highlights if your staff has left any tools inside the equipment or engine being serviced or repaired.

As tool control foam has specific recesses for each tool, those who use these shadow boards also report that it is much easier and faster to find the tool they require. Coupled with laser etching of part numbers or tool names directly onto the foam, shadow boards allow staff to work more quickly and efficiently.

The benefits of foam for tool control

Efficiency and FOD reduction using tool control foam

In addition to allowing engineers to quickly and easily check their tool inventory, using shadow board foam to store tools has several other benefits:

Reduces the risk of foreign object debris

FOD, or foreign object debris, is one of the aviation industry’s biggest dangers. However, it can also cause significant, costly damage to various industrial machinery and equipment.

Keeping tools organised and secure using foam inserts reduces the risk of your team accidentally forgetting tools that could cause severe damage and safety risks.

Improves the engineer's efficiency

When each tool has its own space in the toolbox, it quickly highlights when one is missing. As a result, staff are less likely to lose tools or show up to a job without the tools they need.

When the toolbox is neat and organised, it also helps engineers complete their tasks faster and more efficiently.

Secures tools

Storing tools in a shadow board foam rather than leaving them loose in a toolbox also protects and secures them, preventing damage during transportation.

Reduces expenses related to damage

Specific tools and equipment can be costly, especially for applications requiring specialist equipment.

Storing tools in foam inserts significantly reduces, and can even eliminate, damage caused by mishandling, impact, or vibration. The foam provides cushioning protection, absorbing any forces that could cause them to break.

Improves accountability

Military and commercial engineers, as well as those working in the aviation and aerospace industries, can benefit from improved accountability and audit trails.

Tool control foam can be used in this process.

Summary

Securing shadow boards for tool control

Shadow boards have several inherent benefits for the aerospace industry and a considerable range of other applications. They reduce the risk of foreign-object damage, increase efficiency, keep tools secure, and improve accountability.

At GWP, we have a team of packaging experts with extensive experience in maximising the effectiveness of all types of packaging – including shadow boards, foam inserts, and protective cases. So, if you require assistance optimising your tool control foam, please do not hesitate to get in touch.

About the author

Ian, as one of the founding Directors of GWP, used his broad knowledge to oversee the new business strategy until his retirement in 2025.

Important note

Due to the regulated nature of the topic this guide addresses (aerospace packaging) we have taken extra steps to ensure its accuracy and reliability. You can find out more in our content policy.

All information is, to the best of our knowledge, accurate and correct at the time of publication. Please also note that, as all scenarios vary, not all information contained in this guide may apply to your specific application. There may also be specific regulations or laws, not covered within this particular guide, that apply. Please view the list of aerospace packaging regulations for further details.

Share this article

Further reading

Products in this guide

Get in touch

Related guides

Plastazote® foam – what is it and should you be using it?

Beginners guide to UN3480, UN3481 and IATA regulations

The 6 tell-tale signs you need protective foam inserts

7 tips for shipping high value equipment, tools, and parts

Best equipment cases: choosing a waterproof protector case

Enhancing your protective cases with foam inserts

Equipment damage: 8 causes of products breaking in transit

Shipping cases: 5 options for safe transit of your goods